The DTF printing process, or Direct to Film printing, is revolutionizing the world of custom printing by combining cutting-edge technology with eco-friendly practices. This innovative method allows for the vibrant transfer of designs onto various substrates, particularly garments, providing a versatile solution for businesses looking to create unique apparel. As the popularity of DTF printing technology grows, so does the demand for high-quality, custom prints that meet the diverse needs of consumers. Utilizing eco-friendly inks, this process not only enhances the visual aesthetics of printed items but also aligns with contemporary sustainability efforts in garment printing. Understanding the complexities of the DTF printing process is essential for any entrepreneur aiming to excel in the competitive landscape of custom apparel.

In the realm of garment customization, techniques like Direct to Film (DTF) printing are emerging as powerful alternatives for achieving striking results. This advanced printing approach enables businesses to create unique designs that are seamlessly applied to various materials, including textiles and more. Often recognized for its efficiency and high-quality outputs, DTF printing technology is quickly becoming a preferred choice among professionals in the custom printing industry. The use of eco-conscious inks further enhances its appeal, catering to environmentally-aware consumers and businesses alike. As demand for personalized and sustainable products surges, exploring the DTF process and its associated benefits is crucial for those looking to thrive in today’s market.

Understanding the Basics of DTF Printing Technology

DTF printing, or Direct to Film printing, is an innovative technology that has quickly gained traction within the custom printing industry. At its core, DTF utilizes a specialized film that allows vibrant colors and intricate designs to be transferred to a wide array of fabrics, including cotton and polyester. This method presents a revolutionary approach to garment printing, enabling businesses to produce high-quality prints with ease. The versatility of DTF printing is particularly appealing to small and large businesses alike, as it can cater to both bulk orders and unique, custom pieces.

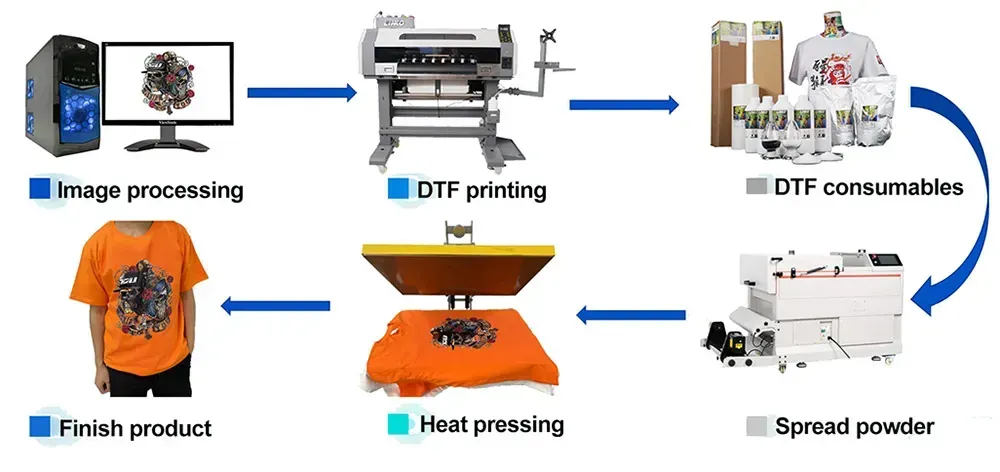

Moreover, the process begins with the creation of a digital design which is printed onto the DTF film. This film is then coated with an adhesive powder that plays a crucial role in the transfer process. Following this, heat and pressure are applied to ensure that the design adheres perfectly to the garment or substrate. The seamless integration between design and printing has made DTF printing a go-to solution for many apparel manufacturers seeking efficiency without compromising on quality.

The Steps Involved in the DTF Printing Process

The DTF printing process comprises several crucial steps that ensure the final product meets the desired quality. Initially, the design creation stage allows graphic designers to use various software tools to develop appealing graphics. This step is vital, as understanding the limitations and advantages of DTF technology will lead to better print outcomes. Moving forward, designers must consider elements such as color fidelity and fabric compatibility, which significantly influence the appeal of the printed item.

Once the design is complete, it is printed onto a specialized film. After printing, it is essential to powder the film with adhesive to facilitate the transfer during the curing process. This is where proper settings for temperature and pressure become pivotal, ensuring that the print adheres seamlessly to the substrate. To finalize the process, a thorough quality check ensures that the print has been transferred correctly and is of high quality, meeting both aesthetic and durability requirements.

Exploring the Benefits of DTF Printing

One of the primary advantages of DTF printing is its ability to produce vibrant, durable designs that stand the test of time. The inks used in this process are often eco-friendly, making it an appealing option for businesses focused on sustainability. DTF printing technology not only offers a vibrant color palette but also provides businesses with the flexibility to print on various materials, ranging from textiles to hard surfaces.

Additionally, DTF opens up opportunities for custom printing that can cater to niche markets. This flexibility is particularly advantageous for businesses specializing in personalized apparel where consumers seek unique designs tailored to their preferences. With advancements in technology continuing to evolve, DTF printing is becoming an indispensable tool for modern manufacturers aiming to stay ahead in the competitive market.

Sustainability in the DTF Printing Industry

Sustainability is rapidly becoming a key consideration within the DTF printing sector. Many companies are pivoting towards using eco-friendly inks that are not only safe for the environment but also maintain high print quality. The shift towards sustainable practices aligns with the growing consumer demand for environmentally friendly products, making it essential for businesses to embrace these changes.

Moreover, as more consumers become aware of their ecological footprint, businesses that adopt sustainable methods can enhance their brand reputation and appeal to a wider audience. Companies utilizing eco-friendly inks in their DTF printing processes are making a conscious effort to reduce chemical waste and energy consumption, thus contributing positively to the environment while meeting consumer expectations.

The Market Prospects for DTF Printing

The DTF printing market is witnessing significant growth, driven primarily by the rising demand for custom apparel. As consumers increasingly seek personalized items that reflect their individual style, businesses are investing in DTF technology to meet these evolving needs. Market analysts predict a robust expansion within the DTF segment, spurred on by innovative printing techniques and a rising interest in custom garment production.

This marketplace expansion offers lucrative opportunities for manufacturers and designers alike. As brands recognize the potential of DTF printing to differentiate themselves in the crowded apparel landscape, they are more likely to explore this technology’s capabilities. Engaging in DTF printing not only enables businesses to cater to the trend of unique, personalized fashion but also positions them favorably in a competitive market.

DTF Printing: Transforming Custom Apparel Creation

DTF printing is transforming the way custom apparel is created, providing designers and manufacturers with a powerful tool to bring their visions to life. This technology supports a diverse range of fabrics and allows for the production of intricate designs that can seamlessly adapt to customer demands. With the ease of integrating DTF printing into existing production lines, businesses can produce high-quality products faster, reducing turnaround time for orders.

Furthermore, the ability to print on a variety of substrates, including non-traditional materials, broadens the scope for creativity in custom designs. This adaptability not only enhances the aesthetic appeal of the products but also enables companies to delve into new markets. As the DTF printing process continues to evolve, it is set to become an essential component of the custom printing landscape, meeting both stylistic and functional needs of modern consumers.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process, or Direct to Film printing, uses a specialized film to transfer vibrant designs onto garments and substrates. This involves creating a design digitally, printing it on the film, applying adhesive powder, and then using heat and pressure to transfer the design onto the desired material, ensuring high-quality results across various fabric types.

What are the benefits of using DTF printing technology for custom printing?

DTF printing technology offers numerous benefits for custom printing, including the ability to print on multiple fabric types, vibrant color output, and cost-effectiveness. This technology has gained popularity due to its versatility and ability to produce intricate designs quickly, meeting the growing demand for customized apparel.

Are the inks used in the DTF printing process eco-friendly?

Many manufacturers are now producing eco-friendly inks specifically for the DTF printing process. These inks maintain high print quality while minimizing environmental impact, aligning with the increasing consumer demand for sustainable practices in custom printing.

What types of materials can be printed using DTF printing?

The DTF printing process is versatile and can print on a variety of substrates, including cotton, polyester, blends, leather, and canvas. This allows businesses to create custom designs for a wide range of items, from apparel to home decor and promotional products.

How can businesses ensure quality in the DTF printing process?

To maintain quality in the DTF printing process, businesses should follow essential steps such as ensuring accurate design creation, correct printer settings, proper adhesive application, and conducting thorough quality checks after heat transfer. These practices help achieve vibrant, professional-looking results.

What is the market growth potential for DTF printing technology?

The DTF printing technology market is projected to grow significantly, with an expected compound annual growth rate (CAGR) of over 15% from 2025 to 2030. This growth is driven by increasing consumer demand for custom apparel, making DTF a lucrative investment for businesses in the printing industry.

| Key Components | Details |

|---|---|

| Technological Advances | Innovations have improved print quality and productivity by reducing downtime. |

| Market Growth | Projected growth of over 15% CAGR due to increasing demand for customized apparel. |

| Design Process | Modern software supports intricate designs, ensuring quality and consistency. |

| Sustainability | Use of eco-friendly inks aligns with consumer expectations for greener practices. |

| Diverse Applications | Applicable on textiles and various substrates, expanding market potential. |

| Steps in Process | 1. Design Creation 2. Printing on Film 3. Curing the Prints 4. Quality Check |

Summary

The DTF printing process is an innovative technique that is reshaping the landscape of custom printing. This method opens doors to creative possibilities, enhancing the quality and efficiency of textile printing while meeting environmental standards. With advancements in technology and a strong growth forecast, businesses venturing into DTF printing can capitalize on the rising demand for personalized and eco-conscious products. Understanding every step of the DTF printing process—from design to quality check—will empower creators to produce eye-catching, high-quality merchandise that appeals to a diverse customer base. This approach not only fosters creativity but also bolsters competitive advantage in the thriving custom apparel market.