DTF transfers, a breakthrough in the realm of custom apparel printing, are rapidly gaining popularity due to their unparalleled efficiency and quality. Unlike traditional printing methods such as screen printing, which often require significant setup and complex workflows, Direct-to-Film printing offers businesses a streamlined approach to create vibrant, durable designs. The advantages of DTF transfers extend beyond mere speed; they also boast lower initial investments and reduced maintenance costs. This revolutionary method allows companies to remain competitive in today’s fast-paced market by meeting consumer demands with flexibility and creativity. By leveraging DTF printing advantages, businesses can open new avenues for success in the custom printing industry.

Direct-to-Film printing technology, often referred to as DTF transfers, is transforming the landscape of textile printing with its innovative approach. This modern printing solution provides a plethora of benefits that outshine traditional methods, making it an essential tool for companies aiming to personalize their apparel offerings. With its capacity for vibrant colors and intricate designs, DTF technology is quickly becoming the preferred choice in customized garment creation. As we dive deeper into how DTF printing enhances operational efficiency and product quality, it becomes clear that this approach is not only a trend but a viable solution for businesses eager to thrive in a competitive market.

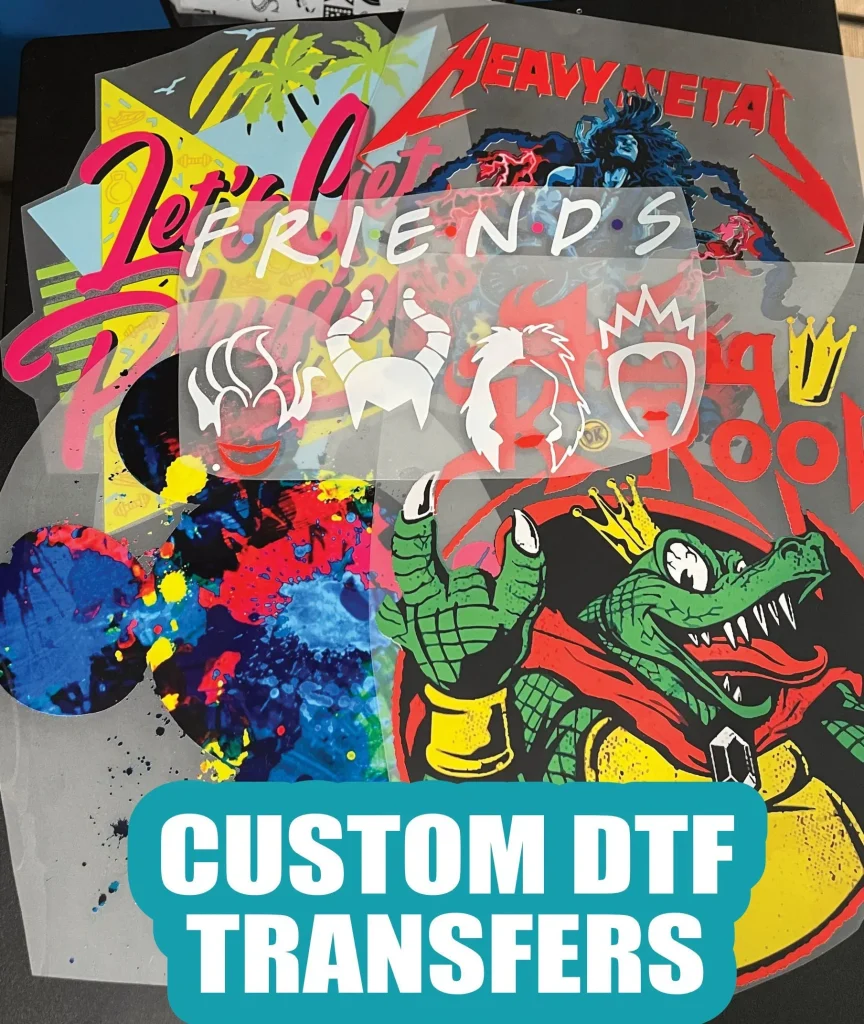

Understanding DTF Transfers

DTF transfers have revolutionized the custom apparel printing landscape by introducing a unique approach to applying designs on garments. Unlike traditional methods such as screen printing, which require intricate setup and a significant investment in materials, DTF printing offers a direct connection between creativity and production. This process uses specialized films and inks, allowing for minimal waste and lower environmental impact, making it an eco-friendly option in contrast to the chemicals often used in conventional methods.

Moreover, the appeal of DTF transfers goes beyond sustainability; they are designed to provide exceptional print quality that meets modern consumer expectations. With the ability to print intricate designs with profound color depth and clarity, businesses can create personalized apparel that stands out in the market. This unique combination of quality and practicality makes DTF transfers a go-to choice for both small startups and established enterprises aiming to cater to increasingly demanding customer preferences.

The Advantages of DTF Printing for Businesses

One of the most compelling advantages of DTF printing lies in its cost-effectiveness. With traditional printing methods, the initial investment can be substantial, requiring businesses to sink significant capital into equipment, setup, and raw materials. In contrast, DTF printing systems typically require a lower upfront investment, enabling businesses, especially smaller ones, to enter the custom apparel market with reduced financial risk. This accessibility empowers new entrepreneurs to offer high-quality products without the common barriers associated with traditional techniques.

Furthermore, DTF transfers bring the added benefit of simplified inventory management. Businesses can produce designs on-demand, which eliminates the need to maintain a large stock of apparel. This flexibility not only enhances cash flow but also allows businesses to adapt swiftly to shifting consumer trends, a crucial factor in today’s fast-paced fashion industry. With demand varying significantly from season to season, DTF technology positions businesses to respond swiftly, thus maintaining a competitive edge.

DTF Printing vs. Traditional Methods: A Comparative Overview

When comparing DTF printing to traditional methods like screen printing and heat transfer, several distinctions come to light. Traditional methods often involve prolonged setup times, especially for complex designs that demand multiple screens or layers. In contrast, DTF transfers significantly reduce preparation time. With DTF, the entire process can be streamlined, permitting quicker turnaround times and allowing businesses to take on more orders without sacrificing quality.

Moreover, traditional methods can encounter limitations regarding color complexity and detail reproduction. Many screen printing processes may struggle with intricate designs or gradients, leading to less satisfactory results. DTF technology, however, excels in producing vibrant, high-resolution prints that maintain their integrity over time. This capability places DTF transfers in a league of their own, particularly appealing for companies targeting high-end markets that prioritize quality and customization.

Cost Analysis: Is DTF Printing Worth It?

Cost is a pivotal factor for businesses weighing their options in custom apparel printing. Traditional printing methods typically entail high upfront costs alongside recurring expenses for maintenance and supplies. In contrast, DTF printing presents a lower entry barrier, where businesses can begin operations with more manageable costs. By comparison, the operational efficiency introduced by DTF transfers could result in significant savings over time, making this method a financially sound investment, especially for startups and growing enterprises.

Indeed, the cost-effectiveness of DTF technology empowers businesses to divert funds toward innovation and marketing rather than being tied up in equipment and inventory expenses. This agility can lead to better pricing strategies and higher profit margins, all while maintaining a competitive quality that appeals to discerning customers. As such, when considering the financial implications, DTF printing frequently proves to be a more attractive option for both new ventures and established firms looking to optimize their production processes.

Versatile Applications of DTF Transfers

The versatility of DTF transfers positions them at the forefront of custom apparel printing solutions. With the capability to print on a diverse range of materials, including cotton, polyester, and blends, DTF technology transcends the limitations imposed by traditional printing methods. This adaptability allows businesses to cater to a broader spectrum of consumer preferences, whether creating athletic wear, casual apparel, or specialized clothing for events.

Additionally, the ability to produce print-on-demand further amplifies the advantages of DTF printing. Companies can design unique pieces tailored to individual customer requests without the necessity of large inventories. This timely response to market demands not only enhances customer satisfaction but also fosters brand loyalty, as businesses can operate with a level of intimacy with their clientele that traditional methods cannot offer.

The Future of Apparel Printing: Embracing DTF Technology

As consumer preferences evolve, the demand for customization within the apparel industry continues to grow. DTF technology is distinctly positioned to meet this trend, providing businesses with solutions that enhance creative freedom while supporting efficient production workflows. The future of apparel printing appears to be leaning toward methods that prioritize both quality and speed, making DTF transfers a key player in this transformative landscape.

Moreover, as technological advancements continue to emerge, the capabilities of DTF printing will only expand. This could lead to even greater efficiencies, allowing for more complex designs to be produced quickly and effectively. For businesses that are ready to adapt and innovate, embracing DTF technology is not just a trend; it represents a strategic move towards remaining competitively relevant in an ever-changing market.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a modern printing technique where designs are printed onto a special film, which are then transferred onto the fabric. This method allows for vibrant colors and intricate designs, effectively competing with traditional printing methods.

What are the advantages of using DTF printing over traditional methods?

DTF printing offers several advantages, including lower initial setup costs, faster production times, and the ability to print on-demand. These benefits make DTF transfers especially appealing for businesses looking to minimize inventory and improve cash flow.

How does the quality of DTF transfers compare to traditional printing methods?

DTF transfers provide high-quality prints that maintain vibrancy and detail, often outperforming traditional screen printing methods. This technology allows businesses to create durable designs that stand up to washes, meeting customer expectations for long-lasting apparel.

Can DTF transfers be used on different types of fabrics?

Yes, one of the significant benefits of DTF printing is its versatility. DTF transfers can be applied to various materials, including cotton, polyester, and blends, making it an ideal solution for custom apparel printing across different fabric types.

What are the cost implications of switching to DTF transfers for my business?

Switching to DTF transfers can result in lower overall costs due to reduced initial investments and minimized inventory needs. This method supports on-demand printing, thus enhancing cash flow and allowing businesses to operate more efficiently.

Is DTF printing suitable for small businesses looking to customize apparel?

Absolutely! DTF printing technology is particularly advantageous for small businesses as it enables high-quality custom apparel printing without the high overhead costs associated with traditional methods. Its scalability allows smaller companies to compete effectively in the market.

| Key Point | DTF Transfers | Traditional Methods |

|---|---|---|

| Initial Costs | Lower initial investments and reduced maintenance costs | Higher upfront costs for equipment and space |

| Efficiency | Faster output with simplified operations | Requires extensive setup and complex workflows |

| Quality | Maintains color vibrancy and detail, produces durable designs | Can struggle with intricate designs and color complexity |

| Cost Flexibility | Print on-demand reduces inventory costs and enhances cash flow | High inventory burden and associated overhead costs |

| Application Versatility | Versatile for various materials and customization options | Limited customization and material compatibility |

Summary

DTF Transfers are emerging as a revolutionary solution in the custom apparel printing industry, allowing businesses to leverage cutting-edge technology for quality production. With advantages such as lower initial costs, enhanced operational efficiency, and superior print quality, companies can meet the dynamic demands of consumers more effectively than ever before. As traditional methods face challenges in flexibility and speed, DTF transfers provide a path for businesses to thrive in a competitive marketplace. By understanding the benefits of DTF transfers, companies can adapt to changing market conditions and position themselves for success.