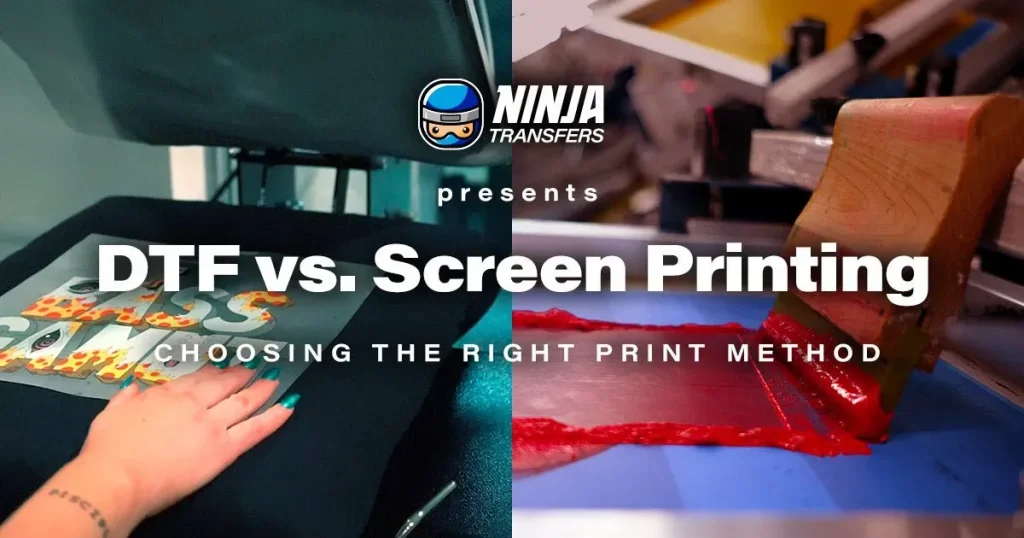

When it comes to DTF Transfers vs. Screen Printing, choosing the right printing method can significantly impact the outcome of your projects. DTF Transfers, or Direct to Film technology, is gaining traction as a modern alternative to traditional Screen Printing, each boasting unique advantages and applications. As we delve into the DTF printing benefits and screen printing advantages, it’s essential to recognize how these two methods compete for the title of the best printing methods for 2025. Understanding their differences allows you to make informed decisions based on the latest printing technology trends, ensuring your designs stand out. In this comprehensive DTF vs. Screen printing comparison, we will explore the features, pros, and cons of both techniques to help you select the ideal approach for your needs.

In the realm of custom apparel production, the debate between DTF Transfers and traditional method of ink application often leads to varying opinions among professionals. DTF, or Direct to Film printing, offers a fresh perspective with its capability to produce high-quality designs that maintain vibrancy and detail. In contrast, the classic technique of Screen Printing has established itself as a reliable choice for bulk orders with its cost-effective and durable results. By examining the key attributes and use cases of these popular printing methods, we can better understand how they cater to different artistic and logistical requirements, especially in light of evolving industry standards and consumer preferences.

Understanding DTF Printing Benefits

DTF printing, or Direct to Film printing, has rapidly gained traction in the fabric printing industry, offering a plethora of benefits that are transforming how custom designs are applied to fabric. This innovative technology allows for vivid color reproduction and fine detail, making it especially suitable for intricate designs and photo-realistic prints. One of its primary advantages is the ability to print on various fabrics—such as cotton, polyester, and blends—without the need for a white underbase, which simplifies the process and expands design possibilities.

In addition, DTF printing is incredibly versatile, making it ideal for both small runs and custom orders. It eliminates lengthy setups and cleaning times commonly associated with traditional printing methods, thus streamlining production and enhancing workflow efficiency. This makes it a favored choice for small businesses that aim to offer unique, high-quality apparel while minimizing operational complexities.

Exploring Screen Printing Advantages

Screen printing has long been regarded as a favorite among bulk production due to its cost efficiency. Once the initial setup is complete, screen printing allows for rapid production, with lower per-unit costs on larger runs. This economic advantage makes it particularly appealing for companies looking to produce promotional merchandise, corporate apparel, or event materials in substantial quantities without sacrificing quality.

Moreover, screen printing is renowned for its durability. The inks used in the screen printing process tend to bond well with the fabric, resulting in long-lasting prints that endure repeated washing and wear. This durability is especially vital for items that may be subjected to regular use, thereby providing value for businesses and clients who prioritize longevity in their printed materials.

DTF Transfers vs. Screen Printing Comparison

When comparing DTF Transfers and Screen Printing, several key factors come into play—each method offers unique benefits that cater to distinct needs. DTF printing excels in color vibrancy and detail, making it the method of choice for complex and visually appealing designs. Additionally, the ability to print on a wide range of materials without a white underbase broadens printing possibilities across diverse applications.

In contrast, Screen Printing shines in the realms of cost-effectiveness and durability, proving to be the more practical option for large orders and simple designs. While it’s less adept at handling intricate artworks compared to DTF, its reliability and long-lasting results have solidified its position in the printing industry for decades. Thus, the choice between these two printing methods ultimately hinges on the specific requirements of individual projects, such as design complexity, volume, and fabric type.

Innovative Printing Technology Trends in 2025

As we look towards the future of printing technology in 2025, both DTF Transfers and Screen Printing are evolving to meet the demands of an increasingly niche market. DTF printing, in particular, is gaining momentum among small to medium-sized businesses aiming to offer customizable products with vibrant, intricate designs. Innovations in ink technology and transfer processes are making DTF a leading option for those prioritizing high-quality, visually appealing prints.

Meanwhile, Screen Printing is adapting to modern trends by incorporating eco-friendly inks and advanced automation techniques. These developments not only enhance the efficiency of the printing process but also align with the rising consumer demand for sustainable production practices. Both printing methods are clearly on the cutting edge of technological advancements, suggesting an exciting future for the printing industry.

Best Printing Methods for Fashion in 2025

In 2025, the best printing methods for the fashion industry will likely encompass both DTF Transfers and Screen Printing, each serving unique niches. DTF’s ability to produce detailed images in vibrant colors will cater to fashion brands that emphasize artistry and intricate designs, making it a go-to choice for high-end apparel and custom collections.

On the other hand, Screen Printing will continue to dominate the mass production of clothing items where efficiency and durability are paramount. As brands look for ways to balance cost with quality, the ability to produce large runs of simple designs that hold up against wear and washing will ensure Screen Printing retains its relevance in the fast-paced fashion landscape.

Analyzing the Limitations of DTF and Screen Printing

While DTF Transfers are remarkably versatile, they do come with their own set of limitations. The upfront costs associated with acquiring specialized equipment can be a barrier for startups or smaller print shops. Furthermore, although DTF is suitable for various fabrics, it may not perform well on all materials, which could restrict creative possibilities for some projects.

On the flip side, Screen Printing also has its drawbacks. The initial setup for printing can be time-consuming, especially for designs that require multiple colors or complex artwork. This method may not be ideal for short runs, as the time to prepare screens does not justify the output for smaller quantities. These limitations underscore the importance of understanding the specific requirements of each project when choosing between DTF Transfers and Screen Printing.

Frequently Asked Questions

What are the key benefits of DTF Transfers over Screen Printing?

DTF Transfers offer several advantages including versatility across fabrics, vibrant color reproduction, and simplicity in setup. Unlike Screen Printing, DTF can achieve photorealistic details and gradients, making it ideal for custom or intricate designs, especially beneficial for small businesses looking for high-quality results.

What are the advantages of Screen Printing compared to DTF Transfers?

Screen Printing is known for its cost-effectiveness, particularly for large orders, as the per-unit price decreases after initial setup. Furthermore, Screen Prints are highly durable and resist fading, making them suitable for garments subjected to heavy use. They also offer unique textures that can enhance the visual appeal of apparel.

How do DTF Transfers and Screen Printing compare in terms of durability?

In a DTF vs Screen Printing comparison, Screen Printing generally outperforms DTF in durability. Screen printed items withstand repeated washing and wear, maintaining their appearance over time. DTF, although versatile, may have limitations on certain fabrics affecting its long-term durability.

What printing technology trends should I consider for my business in 2025?

In 2025, emerging printing technology trends include the rise of DTF Transfers for custom designs and the integration of eco-friendly inks in Screen Printing. Businesses are increasingly adopting these technologies for enhanced quality, efficiency, and sustainability.

When is it better to use DTF Transfers instead of Screen Printing?

DTF Transfers are the better choice for short runs, custom orders, or complex designs requiring fine details and gradients. They excel in applications where fabric variety and vibrant colors are important, making them ideal for fashion and merchandise that demand high-quality detailing.

What potential limitations should I be aware of with DTF vs Screen Printing?

While DTF Transfers are highly versatile, they may involve higher equipment costs and compatibility issues with certain fabrics. Screen Printing, on the other hand, has longer setup times and may not be suitable for intricate designs. Understanding these limitations can guide you in selecting the appropriate method for your project.

| Key Features | DTF Transfers | Screen Printing |

|---|---|---|

| Advantages | Versatile across various fabrics, vibrant colors, easy to use for small runs. | Cost-effective for large batches, durable, and allows for unique textures. |

| Limitations | Equipment costs can be high, and certain fabric compatibility issues may arise. | Setup time can be lengthy, and complex designs are less effective. |

| Best Use Cases | Short runs or custom orders requiring detailed designs; small business applications. | Large corporate orders, simpler designs, and high-volume items. |

Summary

DTF Transfers vs. Screen Printing plays a crucial role in modern printing choices, and making the right selection can significantly impact your project’s success. Understanding the key differences, advantages, and limitations of each printing method is essential for determining which approach suits your needs best. DTF Transfers offer versatility and vibrant imagery, while Screen Printing excels in durability and cost-effectiveness for bulk production. Ultimately, the decision hinges on your specific requirements, including the volume of prints, design complexity, and fabric options. With both printing methods continually evolving, staying informed will help you make choices that enhance your products’ visual appeal and quality.