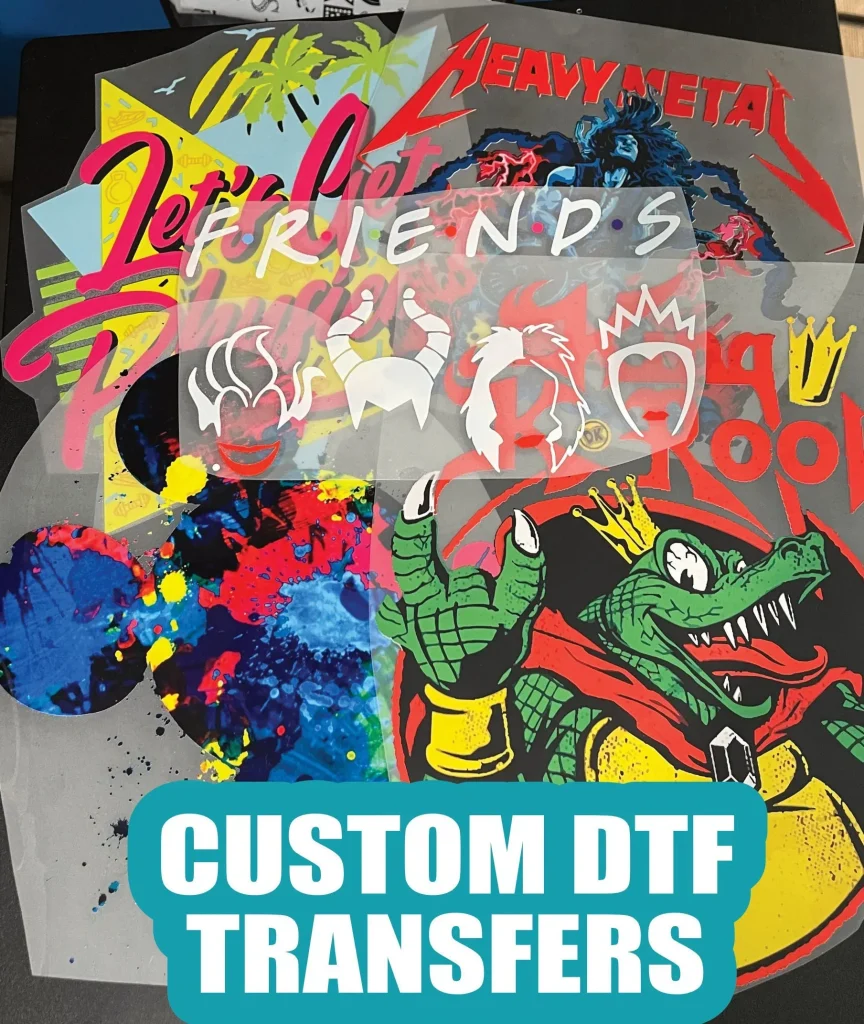

In the dynamic world of custom apparel, DTF transfers have emerged as a groundbreaking method for artists and entrepreneurs to bring their designs to life with precision and flair. DTF printing, which stands for Direct to Film printing, utilizes a unique process to transfer high-quality graphics onto a variety of fabrics, enhancing both vibrancy and durability. This innovative technique is not only ideal for creating eye-catching designs but also provides flexibility in fabric options, catering to everything from t-shirts to hats. For those embarking on their creative journeys, a beginner’s guide to DTF can illuminate the path toward mastering this exciting printing technology. As we delve into the world of heat transfer printing and film transfers, the opportunities for stunning custom apparel seem endless.

Known for its versatility and efficiency, DTF printing is transforming how enthusiasts create custom designs for clothing and accessories. This direct-to-film technique allows for seamless image transfer onto different types of fabrics, making it a standout solution in the field of specialty printing. With user-friendly processes and cost-effectiveness, DTF transfers are allowing beginners to explore their creativity without the complexities of traditional methods like screen printing. Additionally, this cutting-edge approach can be embraced by anyone interested in heat transfer printing, providing a straightforward route to producing custom apparel. As we explore the intricate nuances of this process, you’ll discover how DTF printing can elevate your creative projects to new heights.

Understanding DTF Transfers in Custom Apparel

DTF transfers, or Direct to Film transfers, have garnered a significant following in the realm of custom apparel due to their unparalleled versatility and high-quality output. Unlike traditional methods, DTF printing allows for intricate designs to be printed on various fabric types, including cotton, polyester, and blends. This capability enables designers to explore a wider range of products, from t-shirts to sportswear, without being limited by fabric choice.

The key to successful custom apparel using DTF transfers lies in the preparation and execution of the printing process. Artists and creators can achieve optimal results by choosing suitable high-quality films and inks, which ensures that colors pop and designs remain vibrant after multiple washes. As this technique continues to evolve, its acceptance in fashion and merchandise industries showcases the potential for creativity and personalization.

DTF transfers have transformed the landscape of custom apparel by offering a combination of affordability and quality that appeals to small businesses and individual creators. The ease of use associated with DTF technology allows even beginners to produce professional-grade products without intensive training or expensive equipment. This blend of artistry and practicality has made DTF a preferred choice within the DIY and crafting community.

As the trend towards customization grows, understanding DTF transfers becomes essential for anyone wishing to expand their skills or business. By mastering the techniques involved, users can not only enhance their product offerings but also connect with a broader audience that values unique and personalized apparel.

Benefits of DTF Printing for Beginners

For beginners in the realm of fabric printing, DTF printing offers several compelling advantages that make it an ideal choice. First and foremost, the technology is user-friendly and allows for quick learning. Unlike complex methods such as screen printing, which requires extensive preparation and setup, DTF can be easily understood and implemented, providing newcomers with a faster route to creating stunning designs.

Moreover, the cost-effectiveness of DTF printing cannot be overstated. For small production runs or one-off custom designs, DTF transfers eliminate the need for minimum order quantities that are often a hurdle in traditional printing methods. Beginners can create prototypes and test designs without significant upfront investments, making it a great entry point into the world of custom apparel.

Another highlight of DTF printing is its durability. Unlike other heat transfer processes, DTF prints, once cured properly, exhibit a remarkable adherence to fabric. This longevity means clients can enjoy their custom designs for an extended period, showcasing the quality and resilience that can elevate a beginner’s work to professional standards.

With the availability of extensive online resources and communities, beginners can support their learning journey through tutorials and discussion forums. The collective knowledge within these networks enriches the new user’s experience, making it easy to troubleshoot and enhance their DTF skills.

Getting Started with DTF Printing Equipment

When venturing into DTF printing, selecting the right equipment is essential for achieving high-quality results. A reliable DTF printer and heat press are the core components needed to initiate the printing process. It is advisable for beginners to research brand recommendations from established communities, as these ensure purchased equipment delivers consistent performance and durability.

In addition to printers, investing in high-quality DTF transfer films is crucial. The film acts as a medium for the design, and its quality directly correlates with the clarity and vibrancy of the final print. By sourcing films from reputable suppliers known for their DTF products, beginners can avoid common pitfalls that lead to sub-par results.

Moreover, regular maintenance of all equipment is paramount to sustain longevity and functionality. Keeping printers and heat presses clean and in good working order prevents unexpected failures and ensures that every print session meets quality expectations.

Starting with the right tools and understanding the operational requirements can significantly ease the recommended learning curve associated with DTF printing. Combining quality equipment with practical know-how lays a solid foundation for any beginner eager to succeed in the world of custom apparel.

Essential Tips for Successful DTF Transfers

To ensure successful DTF transfers, newcomers should follow several essential tips that will significantly impact their results. One of the most crucial practices is conducting test prints before committing to larger runs. Testing different settings and materials not only helps in pinpointing the optimal configuration but also provides a learning opportunity to understand how variables affect the final output.

Additionally, immersing oneself in the DTF printing community can prove invaluable. Many beginners benefit from sharing experiences, troubleshooting challenges, and discovering creative ideas through forums and social media groups dedicated to DTF printing. Engaging with fellow enthusiasts fosters a supportive environment where knowledge is readily exchanged.

Also, understanding the characteristics of different fabric types is vital. Each fabric reacts uniquely to heat and pressure, and knowing how to adjust settings for specific materials can drastically improve print quality. Beginners should use this knowledge to experiment with diverse fabric combinations to discover which works best for their designs.

Overall, adhering to these best practices can elevate a beginner’s DTF printing experience, transforming potential frustrations into a fulfilling and creative journey. Embracing experimentation, community engagement, and thorough testing ensures that users achieve impressive results consistently.

Exploring the Community Resources for DTF Printing

The DTF printing community has quickly become a vital resource for beginners looking to enhance their skills and gain valuable insights. Renowned online platforms feature a wide array of tutorials, ranging from basic setup to advanced techniques in DTF printing. Video tutorials on YouTube, hosted by seasoned professionals, offer step-by-step guidance and live demonstrations that demystify the printing process.

Online courses available on educational platforms like Udemy and Skillshare present structured learning pathways tailored to various skill levels. These courses cover critical aspects of DTF printing, helping beginners grasp both foundational concepts and specialized techniques necessary for success.

Moreover, community forums provide a platform for users to ask questions, share experiences, and seek assistance from one another. Engaging in these discussions creates a supportive atmosphere where beginners can connect with industry veterans, leading to invaluable mentorship opportunities.

Taking advantage of these community resources is essential for maximizing the potential of DTF printing. Engaging continuously with expert advice not only enhances skills but also opens doors to new creative avenues, inspiring innovators within the DTF landscape.

Navigating Current Trends in DTF Printing

As the DTF printing landscape evolves, staying in tune with current trends can significantly impact a user’s success. Innovations in ink quality and formulations are at the forefront, improving the vibrancy and lifespan of prints. Brands are introducing eco-friendly inks that cater to the growing demand for sustainable practices, a trend that resonates well with environmentally conscious customers.

Additionally, advancements in DTF printing equipment have made technology more accessible to beginners. New models of printers and heat presses focus on enhancing user-friendliness and efficiency, allowing creatives to set up and start printing with ease. Keeping abreast of these trends ensures that newcomers maximize opportunities for profitability and creativity in their custom apparel businesses.

Another trend to observe is the integration of digital marketing strategies within the DTF community. Many individuals are taking their apparel designs online, utilizing social media platforms to showcase their work and attract customers. Learning these marketing tactics can help beginners not only create stunning products but also effectively promote and sell them in an increasingly competitive market.

Embracing these current trends allows fledgling DTF printers to position themselves strategically within the industry, leveraging new technologies and sustainability practices that resonate with modern consumers. This adaptability is crucial for thriving in the dynamic world of custom apparel.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a printing method where high-quality images are printed onto a special film. Using heat transfer printing techniques, the images from this film can then be applied to various fabrics, including cotton and polyester. This process allows for vibrant, durable designs, making it a popular choice for custom apparel.

How do DTF printing and heat transfer printing differ?

While both DTF printing and traditional heat transfer printing involve transferring images onto fabric, DTF printing utilizes a unique film that results in richer colors and details. Unlike standard heat transfer methods, DTF allows for greater versatility in fabric types, including blends, making it ideal for a variety of custom apparel.

Is DTF printing suitable for beginners?

Yes, DTF printing is particularly beginner-friendly. The setup process is less complex than traditional screen printing, and the availability of user-friendly printing equipment makes it accessible for new entrants in the custom apparel market. Additionally, a growing community offers tutorials and support for novices.

What are the advantages of using DTF transfers for custom apparel?

DTF transfers offer several advantages for custom apparel, including versatility across different fabric types, ease of use, and durability of prints that withstand multiple washes. This makes DTF a cost-effective choice for those looking to produce small batches or specialized designs.

What types of fabrics can DTF transfers be applied to?

DTF transfers can be applied to a wide range of fabrics, including cotton, polyester, and various fabric blends. This adaptability makes DTF printing suitable for numerous custom apparel products, from t-shirts to bags and more.

Where can I find resources to learn more about DTF printing?

There are many resources for learning about DTF printing, including online platforms like YouTube for tutorials, and educational sites like Udemy or Skillshare for structured courses. Engaging with DTF communities online can also provide valuable insights and practical tips for beginners.

| Key Points | Details |

|---|---|

| Introduction | DTF (Direct to Film) printing revolutionizes custom apparel by transferring designs onto fabric with ease and quality. |

| What is DTF Printing? | A process transferring high-quality images from film to fabric, allowing versatility across different materials. |

| Key Benefits of DTF Transfers | Includes versatility across fabrics, ease of use, durability, and cost-effectiveness for small runs. |

| Current Developments | Improved ink quality, evolving equipment, and growing community support enhance DTF printing. |

| Practical Tips for Beginners | Invest in quality equipment, use high-quality films, conduct test prints, and maintain tools for best results. |

| Resources for Learning | YouTube tutorials and online courses provide guidance for mastering DTF techniques. |

Summary

DTF transfers are an innovative and approachable way for beginners to engage in custom apparel design, merging technology with creativity. As you explore the capabilities of DTF printing, you will discover the versatile applications and vibrant results it can achieve on various fabrics. This method not only enhances your ability to create stunning visuals but also simplifies the printing process compared to traditional methods. The ongoing advancements in ink quality and equipment, along with the support of a growing community, make DTF transfers a promising avenue for anyone looking to bring their design ideas to life with impressive clarity and durability. Embrace the future of textile printing and unlock the potential of DTF transfers today.