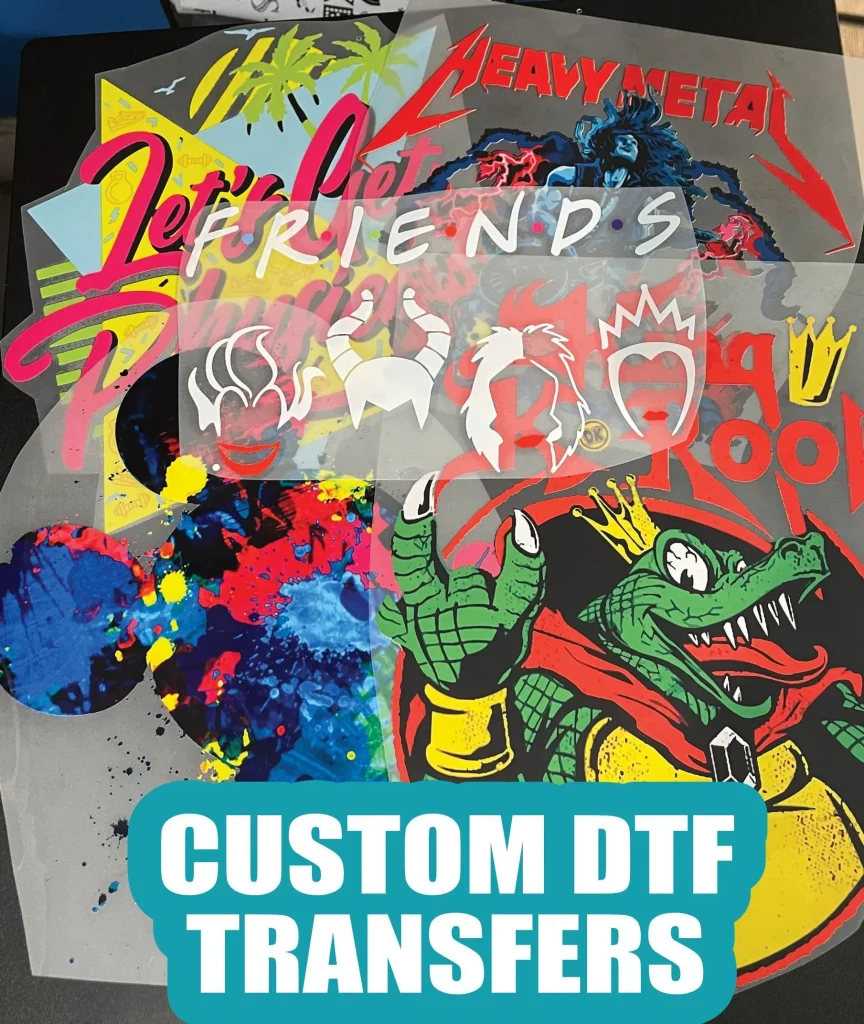

DTF transfers are revolutionizing the world of t-shirt printing in 2023, introducing a game-changing approach that blends high quality with customization. This innovative DTF printing technology utilizes a unique direct-to-film process, allowing for vibrant and detailed designs that cater to diverse fabric types. As the demand for custom apparel surges, these digital printing techniques are poised to provide businesses with unparalleled versatility and efficiency. Moreover, DTF transfers align with sustainable printing methods, utilizing water-based inks and recyclable materials, making them an eco-conscious choice for brands. With this blend of creativity and responsibility, DTF transfers are setting the benchmark for the future of garment decoration.

When discussing DTF transfers, one might encounter terms like direct-to-film printing or modern textile transfers. This advanced printing method delivers exceptional results by applying intricate designs directly onto various fabrics, including cotton and polyester. The ease of digitized apparel application not only increases design possibilities but also enhances durability, with prints that resist wear and wash fading. Additionally, as custom print-on-demand solutions gain popularity, this technology plays a critical role in streamlining production while reducing environmental impact. For businesses looking to innovate in the apparel sector, understanding these contemporary digital printing techniques becomes essential.

The Rise of DTF Transfers in Custom Apparel

As the demand for custom apparel continues to grow, DTF transfers have emerged as a revolutionary technology that caters perfectly to this market. This method enables designers to create intricate, colorful graphics with relative ease. Unlike traditional techniques that often limit creativity due to setup costs or material restrictions, DTF printing provides a more flexible option, allowing businesses to accommodate small and personalized orders efficiently. Additionally, the remarkable detail and vibrant colors achieved through DTF printing ensure that custom designs stand out in an increasingly crowded market.

In the world of custom apparel, versatility is key. DTF transfers shine in this regard, as they can be applied to various materials, including cotton, polyester, and blends. This makes them highly attractive not just for t-shirt printing but for creating unique pieces across different fabric types. As more brands recognize the potential of DTF technology for customization, we’re likely to see a surge in its adoption, further cementing its role as a frontrunner in the custom apparel narrative.

Advantages of DTF Printing Technology

One of the significant advantages of DTF printing technology is its cost-effectiveness, particularly for smaller businesses. Traditional methods, such as screen printing, often require substantial investments in equipment and materials, especially when dealing with varied colors and designs. In contrast, DTF transfers simplify the process by allowing for multiple designs to be printed on a single film, significantly reducing overhead costs. This flexibility allows entrepreneurs to explore creative avenues without the burden of high initial expenses.

Furthermore, the speed at which DTF prints can be produced is a crucial factor in the modern apparel market. Businesses facing tight deadlines benefit immensely from the quick turnaround times associated with DTF technology. This efficiency not only helps meet customer demands but also allows companies to experiment with designs and variations frequently, enhancing their overall market competitiveness.

Sustainable Printing Methods with DTF

In an era where sustainability is a priority, DTF printing stands out as a more eco-friendly option compared to many traditional printing methods. With manufacturers increasingly shifting towards water-based inks and recyclable materials, DTF technology aligns well with the goals of environmentally conscious consumers. This commitment to sustainable practices indicates a potential for the DTF printing industry to evolve in a way that supports both creative expression and ecological responsibility, appealing to a broad scope of consumers who prioritize sustainability.

Additionally, the reduction of waste associated with DTF transfers also contributes to its sustainable appeal. By using a direct-to-film approach, the need for extensive setup and materials is minimized, meaning less waste is generated during the printing process. As brands look to position themselves as environmentally friendly, embracing DTF printing technologies could not only fulfill consumer expectations but also set a standard for sustainable practices in the apparel industry.

The Process of DTF Printing: Step by Step

DTF printing involves a unique process that begins with printing images onto a special film. This film serves as the carrier for the transferred image, which can then be applied to various fabrics using a heat press. The first step includes designing the artwork digitally, allowing for intricate details and vibrant colors that are characteristic of DTF prints. After printing, a powder adhesive is applied to the wet ink, which is then cured under heat, preparing it for the transfer process.

Once the film is ready, the transfer process begins by aligning it correctly on the fabric. Using a heat press, heat and pressure are applied, which ensures that the image adheres to the fabric properly. This method not only produces high-quality results but also guarantees wash durability, making DTF transfers an appealing option for custom apparel that must withstand regular use. This comprehensive process highlights DTF printing as not just a method but a sophisticated technology that elevates traditional t-shirt printing techniques.

Current Market Trends Impacting DTF Transfers

As we move through 2023, several market trends are shaping the landscape of DTF transfers in the t-shirt printing industry. A notable trend is the increased adoption of DTF technology by small businesses and startups that seek a cost-effective method to enter the custom apparel market. This democratization of technology allows creatives and entrepreneurs to bypass the high entry barriers traditionally associated with garment printing.

Moreover, the continuous advancements in DTF printing technology, including better inks and printers, are enhancing the viability and appeal of this method. With improvements in color fidelity and print longevity, brands are filled with confidence as they incorporate DTF transfers into their production line. This growing confidence among businesses further solidifies DTF technology’s position as a critical player in the future of custom apparel.

The Future of Custom T-Shirt Printing with DTF

Looking forward, DTF printing is poised to reshape the future of custom t-shirt printing dramatically. Increasing consumer expectations for personalization and quick delivery will drive the proliferation of DTF technology across various segments of the apparel industry. As businesses strive to meet these demands, ongoing innovations will likely focus on enhancing printing speed and quality, ensuring that DTF remains competitive against other printing methods.

Additionally, as sustainability continues to be an essential consideration for consumers, those businesses that leverage DTF printing technology can tap into a growing market segment that values eco-friendly options. The convergence of consumer demand for high-quality, customizable apparel and advancements in DTF technology suggests a promising future for this method, ensuring it remains at the forefront of the t-shirt printing industry.

Frequently Asked Questions

What are DTF Transfers and how do they work in t-shirt printing?

DTF transfers, or Direct-to-Film transfers, involve a printing process where vibrant images are printed onto a specialized film. This film is then heat-pressed onto various fabrics, such as cotton or polyester. Unlike traditional printing methods, DTF allows for intricate designs that resist peeling and maintain wash durability, making it ideal for custom apparel.

What are the advantages of using DTF printing technology for custom apparel?

DTF printing technology offers numerous advantages, including high print quality with vibrant colors and intricate details, versatility across different fabric types, and cost-effectiveness for small runs. Additionally, it enables faster turnaround times, which is crucial for businesses catering to fast-paced consumer demand.

How does DTF printing compare to other digital printing techniques?

Compared to other digital printing techniques, DTF printing excels in color fidelity, durability, and versatility. It allows for detailed designs on various fabric types without the need for extensive setup, which is often required in methods like screen printing. This makes DTF a preferred choice for businesses targeting custom apparel markets.

Is DTF printing a sustainable option compared to traditional methods?

Yes, DTF printing is increasingly considered a sustainable option within the printing industry. Many DTF processes utilize water-based inks and recyclable films, reducing environmental impact. This aligns with the growing demand for more eco-friendly printing methods among consumers and brands alike.

What current trends are shaping the DTF transfers market for t-shirt printing in 2023?

In 2023, the DTF transfers market is being shaped by increased adoption among businesses, technological advancements in inks and printing equipment, and a significant focus on sustainability. These trends reflect a shift towards customization and on-demand printing, driven by consumer preferences for unique and environmentally conscious products.

What should businesses consider when adopting DTF technology for their printing needs?

When adopting DTF technology, businesses should consider the initial investment in DTF printers and consumables, the range of fabrics they wish to print on, and their target market for custom apparel. Understanding the benefits of DTF, such as fast production times and high-quality prints, can help them effectively meet consumer demands.

| Key Points | Details |

|---|---|

| Overview | DTF (Direct-to-Film) transfers are a modern printing technology gaining popularity in the t-shirt printing industry for their versatility and quality. |

| Process | The process involves printing images onto a special film which is then transferred onto fabrics using a heat press. |

| Advantages | 1. Versatility across various fabrics. 2. High print quality with resistance to peeling. 3. Cost-effective for small runs. 4. Faster turnaround times. |

| Current Trends | 1. Increased adoption in custom apparel. 2. Ongoing technological advancements. 3. Rise in sustainability practices in printing. |

| Future Outlook | The demand for DTF transfers is expected to grow, driven by trends in customization and sustainability. |

Summary

DTF Transfers are revolutionizing the t-shirt printing industry in 2023. As businesses increasingly look for ways to meet consumer demand for high-quality, customizable apparel, DTF technology stands out due to its versatility, exceptional print quality, and cost-effectiveness. By allowing intricate designs to be easily transferred onto a variety of fabrics, DTF transfers not only enable rapid production but also address sustainability concerns with eco-friendly practices. As the printing landscape continues to evolve, embracing DTF transfers could be crucial for businesses aiming to thrive in the competitive world of garment printing.