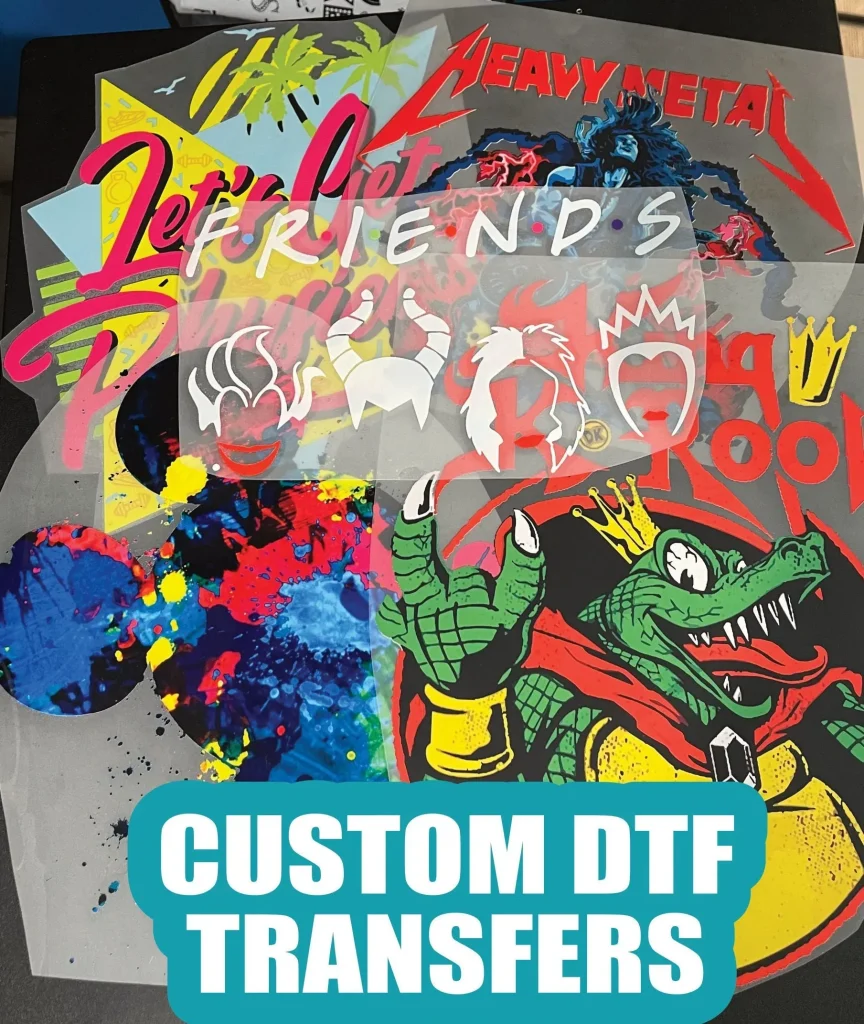

DTF transfers, short for Direct-to-Film printing, represent a groundbreaking innovation in the realm of fabric design, making it easier than ever to create stunning and vibrant fabric designs. This modern technique involves printing designs onto a special film, which is then heat transferred onto various fabrics, allowing for intricate and colorful imagery that captures attention. As the demand for sustainable fashion printing grows, DTF transfer techniques shine through by minimizing waste while delivering high-quality results. With its ability to produce durable prints that stand the test of time, DTF transfers are becoming the go-to option for designers and hobbyists alike. Discover how this method can transform your creations and elevate your artistic expression as we delve deeper into the transformative world of DTF technology.

Direct-to-Film printing, often referred to as DTF transfers, is revolutionizing the way designers approach fabric decoration by providing a user-friendly solution for producing eye-catching textile designs. This advanced printing technology utilizes specialized film to transfer vivid images onto fabrics, ensuring that each design maintains its brilliance and longevity. With a growing emphasis on eco-friendly production methods, the utilization of DTF transfers supports sustainable fashion printing practices that resonate with the environmentally-conscious consumer base. These innovative techniques not only cater to aesthetic demands but also facilitate the creation of unique and vibrant fabric designs that can cater to diverse markets. Join us as we explore the myriad of possibilities DTF technology offers for both professional and aspiring fabric artists.

Understanding the DTF Transfer Process

DTF transfers are a revolutionary printing method that utilizes a specialized film to apply vibrant designs directly to fabric. The process begins by printing your design onto this film using DTF inks, which are specially formulated to ensure bright colors and high durability. Once printed, the film is then heat-pressed onto the selected fabric, allowing for a strong and lasting bond. This technique has surged in popularity, especially among small business owners and hobbyists, due to its balance of quality and low cost.

One of the standout features of DTF printing is its versatility with various fabric types. It works wonderfully on cotton, polyester, and even blends, allowing designers to explore a range of options for their projects. As a sustainable choice, DTF technology minimizes waste compared to traditional methods, making it an attractive option for eco-conscious creators. Knowing how to navigate the DTF transfer process effectively can significantly enhance the quality and appeal of your fabric designs.

Material Selection for Optimal DTF Results

Choosing the right materials is crucial when embarking on your DTF transfer journey. The quality of DTF films and inks directly correlates with the vibrancy and longevity of your fabric prints. High-quality films have a smooth surface that allows for better ink adhesion and more vivid color output. Alongside selecting high-grade materials, testing out different fabric types will reveal the best combinations. Materials with a tighter weave generally provide improved results with DTF transfers.

This careful consideration of materials extends beyond just the DTF film. It’s equally important to select the appropriate fabric to achieve your desired outcome. Cotton and polyester both offer unique benefits that affect print quality and feel. Cotton lends a soft touch and excellent breathability, while polyester tends to make colors pop and is less prone to fading. Exploring a variety of fabric choices can lead to discovering new textures and finishes that elevate your creative projects.

Innovations in DTF Technology

Recent advancements in DTF technology are propelling this printing method to the forefront of the fabric design industry. Innovations in ink formulations have resulted in colors that are not only striking but also incredibly durable, ensuring that your designs can withstand frequent washing and general wear. These improved inks also adhere better to various fabrics, creating a more cohesive and long-lasting print.

Another technological leap includes enhancements in film composition, which have improved compatibility with different heat press settings. These developments allow for more flexibility in production, whether you’re creating individual pieces or bulk orders. As DTF technology continues to advance, users benefit from reduced production times and an overall increase in print quality, cementing its place as a leading choice for sustainable fashion and vibrant fabric designs.

Effective Design Preparation Techniques

Preparing your design with precision is a fundamental part of achieving great results with DTF transfers. This phase involves creating high-resolution artwork that not only captivates the eye but also translates well to fabric. Popular design software like Adobe Illustrator or CorelDRAW offers tools to ensure your designs maintain clarity and vibrancy throughout the transfer process. A well-prepared design directly impacts the quality of the final print, making this step crucial for achieving your artistic vision.

Equally important is the understanding of color profiles and their significance in DTF printing. Utilizing the correct color settings can prevent discrepancies between your digital designs and the finished product. For instance, colors that appear vibrant on screens must be carefully matched when printed, as variations can arise from different materials and inks. Mastering the nuances of design preparation not only enhances the vibrancy of your fabric designs but also ensures consistency in quality across multiple projects.

Heat Press Settings for DTF Transfers

Getting your heat press settings correct is essential for a successful DTF transfer process. Ideal temperatures usually range between 315°F to 330°F, but depending on your specific materials, adjustments may be necessary. Too high temperatures can damage the fabric, while too low may result in poor adhesion. It’s important to consult the instructions provided by your film and ink manufacturers for the best results.

Pressure also plays a critical role in the heat press process. Different fabrics require different levels of pressure to achieve optimal bonding between the DTF transfer and the fabric. Understanding the thickness of your material will help you calibrate your heat press accordingly. Taking these factors into consideration can lead to achieving vibrant, long-lasting transfers that maintain their quality throughout their use.

Sustainability in DTF Transfers

As awareness of sustainability grows in the fashion and printing industry, DTF transfers emerge as a more eco-friendly alternative to traditional printing methods. This technology reduces waste significantly by using less water and energy during the production process. Furthermore, the ability to print multiple designs without extensive setup time minimizes the overall environmental impact, aligning with the shifting focus towards sustainable fashion practices.

Many consumers now prioritize sustainability in their buying decisions, and DTF printing meets these demands by providing a method that is both stylish and responsible. By opting for DTF techniques, you’re not only producing eye-catching fabric designs but also contributing to a movement that values environmentally-conscious production practices. This makes DTF transfers not just a practical choice but an ethical one as well.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film and then using heat to transfer those designs onto fabric. This technique allows you to create vibrant, detailed designs that are durable and effective on various fabric types, making it a popular choice in sustainable fashion printing.

What are the advantages of using DTF transfer techniques for fabric printing?

DTF transfer techniques offer numerous advantages, including the ability to produce vibrant fabric designs with intricate details. Additionally, DTF printing is eco-friendly, as it reduces waste compared to traditional printing methods, aligning with the goals of sustainable fashion.

How can I ensure the best results when using DTF transfers?

To ensure the best results with DTF transfers, focus on selecting high-quality materials, preparing your designs in high resolution, and adjusting heat press settings correctly. Proper pre-treatment of fabrics and post-processing steps, like wash tests, are essential for maintaining the vibrancy of your prints.

What types of fabrics are best suited for DTF transfers?

DTF transfers work well on a variety of fabrics, including cotton, polyester, and blends. Experimenting with different fabric types can help you discover which combinations yield the best vibrant results and durability, helping you create stunning fabric designs.

Is DTF printing a sustainable option for fashion printing?

Yes, DTF printing is considered a sustainable option for fashion printing. This technique reduces waste during the printing process and utilizes eco-friendly ink formulations, making it a suitable choice for environmentally conscious consumers looking to support sustainable fashion practices.

Are there any common mistakes to avoid with DTF transfers?

Common mistakes with DTF transfers include using low-quality materials, incorrect heat press settings, and insufficient design resolution. To avoid these pitfalls, always select high-quality films and inks, adjust temperatures and pressures based on fabric type, and ensure your designs are prepared at high resolution for optimal vibrancy.

| Key Topic | Description |

|---|---|

| What are DTF Transfers? | DTF transfers allow designs to be printed on a film and transferred to fabric using heat, providing vibrant and intricate results. |

| Benefits of DTF Transfers | Cost-effective, sustainable, and capable of producing long-lasting, vibrant designs. |

| Material Selection | Choose high-quality DTF films and inks and experiment with different fabrics for best outcomes. |

| Design Preparation | Use high-resolution artwork and design software to ensure clarity and vibrancy. |

| Heat Press Settings | Optimal temperatures are usually between 315°F to 330°F, with pressure adjustments based on fabric thickness. |

| Pre-treatment of Fabrics | Certain fabrics may need pre-treatment to enhance ink adhesion and prevent peeling. |

| Post-Processing | Conduct a wash test after application to ensure durability and adhesion under normal conditions. |

Summary

DTF Transfers provide a dynamic and efficient way to create stunning fabric designs, combining vibrant colors and sustainable practices. By focusing on quality materials, precise design preparation, and following essential techniques for application and post-processing, creators can harness the full potential of DTF Transfers. This innovative method not only meets the artistic needs but also aligns seamlessly with the growing demand for environmentally friendly solutions in the printing industry. As you explore the world of DTF Transfers, you’ll find endless opportunities to bring your creative visions to life.