DTF Transfers, or Direct to Film transfers, have carved out a unique niche in the world of custom apparel printing. This innovative technique not only allows for the creation of detailed and vibrant designs but also simplifies the transfer process onto various materials. Whether you’re a novice seeking to personalize a simple t-shirt or an experienced designer aiming to expand your collection, understanding how DTF printing works is essential. In this tutorial, we will navigate through the intricacies of DTF transfers, exploring the necessary tools and techniques to achieve stunning results. As we delve into our detailed DTF transfer tutorial, prepare to unlock new creative possibilities in your design journey.

Elevating your custom garment designs has never been easier with the cutting-edge processes involved in DTF printing, also known as Direct to Film technology. This method seamlessly combines intricate graphic creation with heat transfer techniques, allowing for intricate designs that adhere beautifully to fabric. If you’ve ever wondered about the best ways to personalize clothing or create merchandise, learning how to use DTF transfers could be your next step. In this guide, we will explore alternative methods of apparel decoration and how DTF provides unique advantages over traditional methods such as screen printing or vinyl transfers. Get ready to embrace a new realm of creative expression in custom apparel printing!

Understanding DTF Printing: A Key to Custom Apparel Innovation

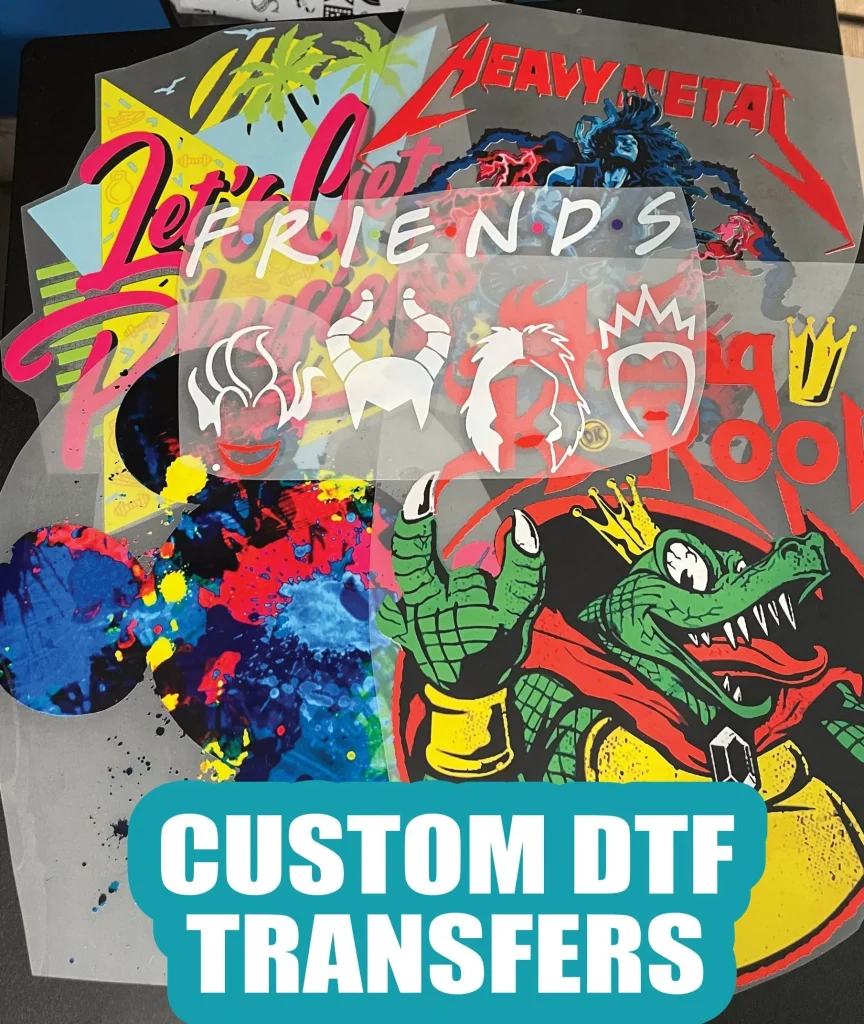

DTF (Direct to Film) printing has emerged as a revolutionary technique in the custom apparel printing industry, capturing the interest of both hobbyists and professional creators. This method stands out due to its ability to transfer intricate and colorful designs onto fabrics with remarkable ease. Unlike traditional printing methods, DTF printing allows for vibrant colors and details that can elevate any apparel item. The versatility of DTF transfers opens up opportunities for creating unique designs on a variety of materials, making it a favorite among those looking to personalize clothing.

Moreover, the DTF printing process incorporates the use of specialized inks and films that enhance the final product’s wearability and longevity. This means that when you produce custom apparel using DTF transfers, you’re not just creating visually appealing designs but also ensuring durability that can withstand repeated washing and wearing. Consequently, businesses and creators alike can focus on their artistic vision while relying on DTF technology to deliver professional-grade results.

Step-by-Step Guide to Using DTF Transfers for Beginners

If you’re new to the world of custom apparel printing, understanding how to use DTF transfers is crucial for producing high-quality designs. The first step in the DTF transfer tutorial involves creating a stunning design using graphic design software like Adobe Illustrator or CorelDRAW. It’s essential to maintain a high resolution to ensure the clarity of your design is preserved throughout the printing process. After designing, you’ll need to print onto the DTF transfer film and carefully apply the adhesive powder, which is integral for the transfer process.

Once the adhesive is applied, curing it is critical to ensure that it bonds properly with the design before transferring it onto your chosen fabric. The final step involves the heat pressing of your design at the right temperature and time, which is typically around 320°F for about 15 seconds. Following these steps not only simplifies the process but also equips you with the skills necessary to create stunning items such as t-shirts and tote bags that can showcase your creativity.

Essential Materials for Successful DTF Printing Projects

To achieve the best results with DTF transfers, having the right materials is essential. The core components required include a DTF printer compatible with specialty inks, DTF transfer films, and high-quality DTF ink. Each of these items plays a significant role in ensuring that your transfers produce vibrant and long-lasting designs. Additionally, investing in good powder adhesive is necessary; it helps the ink adhere to the fabric during the heat transfer process, guaranteeing a professional finish.

Besides the printer and inks, a reliable heat press machine is crucial for applying your DTF designs to fabric effectively. Furthermore, employing protective sheets can help avoid any mess during heat pressing and preserve both your press and the apparel you work with. By ensuring that you have all the necessary materials prepared beforehand, you set yourself up for a seamless and successful DTF printing experience.

Tips for Maximizing Your DTF Transfer Success

When embarking on your journey with DTF printing, implementing certain tips can help enhance your overall success significantly. Firstly, it’s vital to conduct temperature and pressure tests on different types of fabric, as each requires specific settings to achieve the best results. Identifying the ideal combination for your DTF transfers can drastically improve the final appearance and longevity of your designs, making them more appealing in the competitive market.

In addition to testing, using high-quality materials is another tip that can’t be overlooked. From inks to film and adhesive powders, opting for superior quality products will ensure that your designs maintain their vibrancy and durability over time. Experimentation is also encouraged; play around with various patterns, layering techniques, and color schemes to discover unique designs that resonate with your target audience.

Exploring Applications of DTF Transfers in Apparel Design

The versatility of DTF transfers extends beyond mere fashion; they are applicable in a wide range of apparel designs. Custom t-shirts are perhaps the most common application, allowing individuals and businesses to create personalized designs for events, promotions, or individual wear. However, DTF transfers can also enhance items like hoodies, caps, bags, and even custom socks, broadening the creative possibilities for apparel makers.

Moreover, businesses can leverage DTF printing for creating unique merchandise that reflects their brand identity. By incorporating vibrant and intricate designs, companies can attract customers and create memorable promotional items. This adaptability is one of the key reasons why DTF transfers are becoming increasingly popular among creators looking to expand their design offerings in an ever-evolving market.

Unleashing Creativity with DTF Transfer Techniques

DTF printing opens up a world of creativity, offering designers the ability to design intricate and colorful graphics with relative ease. Utilizing heat transfer techniques allows for the application of these vibrant designs to a variety of fabrics, making it possible to tailor unique items that cater to specific tastes and styles. As you get comfortable with the DTF transfer process, you can explore various artistic techniques that will allow your designs to stand out in a crowded market.

In addition to traditional techniques, experiment with layering colors and creating textures using DTF transfers. The ability to produce rich, detailed designs means that you can step away from conventional styles and push creative boundaries. Whether you are designing for personal use or commercial purposes, DTF printing can help unlock your artistic potential and enable you to create stunning items that resonate with customers.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film that can be heat-pressed onto various fabrics. This method allows for vibrant colors and detailed designs, making it ideal for custom apparel printing. The process includes printing, applying adhesive powder, curing, and transferring onto the fabric.

Why should I choose DTF printing for my custom designs?

Choosing DTF printing for your custom designs is beneficial due to its vibrant color output, durability, and ease of use. DTF transfers can produce detailed and complex images that adhere well to a variety of fabrics, allowing for high-quality results in custom apparel printing.

What materials do I need for DTF transfers?

To successfully create DTF transfers, you will need a DTF printer, DTF ink, DTF transfer film, powder adhesive, a heat press machine, weeding tools, and protective sheets. These materials ensure that your DTF printing process is effective and produces high-quality results.

What is the step-by-step process of using DTF transfers?

The step-by-step process for using DTF transfers includes: 1) Create a high-resolution design using graphic software; 2) Print your design on DTF transfer film; 3) Apply adhesive powder; 4) Cure the adhesive; 5) Heat-press the design onto your fabric; and 6) Allow it to cool before peeling off the film.

How can I ensure the best results with DTF transfers?

To ensure the best results with DTF transfers, use quality materials, test varying temperatures and pressure on different fabrics, and take the time to experiment with your designs. Following these practices can enhance the durability and vibrancy of your custom prints.

Are there specific fabrics suitable for DTF transfers?

Yes, DTF transfers work well with a wide variety of fabrics, including cotton, polyester, and fabric blends. This versatility makes DTF printing an excellent choice for anyone looking to create custom apparel or merchandise.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF (Direct to Film) transfers allow printing intricate designs on a special film that can be applied to various fabrics. This method is popular among designers and DIY enthusiasts. |

| Advantages of DTF Transfers | 1. Vibrant Colors: Capable of producing detailed and colorful designs. 2. Durability: Long-lasting results that resist fading and cracking. 3. Ease of Use: Minimal skills required, ideal for beginners. |

| Necessary Materials | 1. DTF Printer 2. DTF Ink 3. DTF Transfer Film 4. Powder Adhesive 5. Heat Press Machine 6. Weeding Tools 7. Protective Sheets |

| Step-by-Step Process | 1. Design Creation: Use high-resolution graphic design software. 2. Print Design: Flip image before printing. 3. Apply Adhesive Powder: Evenly cover printed design. 4. Cure Adhesive: Use oven or press to solidify. 5. Transfer the Design: Heat press on fabric. 6. Cooling and Peeling: Wait to peel transfer film. |

| Successful Tips | Test temperature and pressure; use quality materials; and experiment creatively with designs. |

| Applications of DTF Transfers | 1. Custom T-Shirts 2. Hoodies and Apparel 3. Merchandise for promotional items |

Summary

DTF Transfers provide an exceptional method for creating stunning designs that elevate apparel and merchandise to new heights. As outlined in this tutorial, the DTF transfer process is not only straightforward but offers vast creative possibilities. By following the procedures carefully—from design creation to transfer application—you can achieve professional-quality results that resonate with customers. With the right materials and techniques, embracing DTF Transfers will undoubtedly enhance your craft, whether you’re building a business or expressing your personal style.