DTF transfers, or Direct-to-Film printing, are transforming the textile printing landscape by offering an efficient and innovative way to reproduce vibrant images on various fabrics. This advanced DTF printing process utilizes water-based inks and heat transfer technology to ensure high-quality prints that are both durable and aesthetically pleasing. As we navigate through the intricacies of DTF transfers, we will uncover the stages involved, from design creation to the final heat pressing application. Additionally, the evolution of sustainable printing methods within this sector highlights the growing importance of environmentally conscious practices in modern printing techniques. For artists and businesses seeking creative possibilities, understanding DTF transfers opens the door to a world of design potential.

Known by various names, such as Direct-to-Film printing and DTF technology, this innovative approach to digital printing on fabric introduces a refreshing alternative to traditional methods. The DTF printing method streamlines the process of transferring designs, making it a favorite among custom apparel creators and textile manufacturers alike. By employing a unique blend of specialized films and eco-friendly inks, this technique reflects a significant shift toward sustainable printing methods that consider environmental impacts. As we explore the DTF transfer mechanisms, it’s essential to grasp how these digital solutions not only enhance creativity but also cater to the demands of a green-conscious market. This comprehensive understanding of DTF technology will enable artists and entrepreneurs to redefine their approach to fabric printing.

Understanding the DTF Printing Process

The Direct-to-Film (DTF) printing process is revolutionary in the realm of textile applications, offering a seamless method for fabric transfer that precision and quality demand. This process starts with the meticulous design creation stage where artists utilize advanced graphic design software. High-resolution images ensure clarity and detail, significantly impacting the final print’s vibrancy and professional appearance. Furthermore, understanding nuances like color accuracy and image positioning is vital for producing exemplary fabric transfers.

As the process unfolds, the printed image is created using a specialized DTF printer with eco-friendly water-based inks, making it a step towards sustainable printing methods. The transition from digital design to physical film allows artists and businesses to create unique, high-quality fabric applications, representing a marked improvement over traditional printing methods. This synergy of technology and creative design is shaping the future of fabric printing.

Key Stages in the DTF Transfer Process

In the DTF transfer process, several key stages are essential for ensuring a high-quality print. After the initial design creation, the next step involves printing on a special PET film. This stage is crucial, as the quality of the print directly influences the outcome of the final product. Careful attention during printing processes ensures even ink distribution, which is necessary for vibrant results. Moreover, utilizing advanced DTF printers designed for textile applications ensures optimal fabric compatibility.

Following the printing stage, powder adhesion is applied to the wet ink. This crucial step enhances the durability of the final print, making sure it withstands washing and regular use. Curing the adhesive through a heat process ensures that all elements bond effectively, which is pivotal to achieving the desired outcome. Each stage of the DTF transfer is interconnected, leading to a final product that meets and exceeds expectations.

The Importance of Design in DTF Printing

Design creation is a fundamental aspect of the DTF printing process, where precision and creativity merge to form high-quality prints. Designers often focus on creating visually appealing graphics that will retain their integrity when transferred onto various fabrics. The collaboration between technological capability and artistic vision is what gives DTF transfers their unique edge in the market. By leveraging graphic design software, artists can tweak their images for clarity and impact, ensuring that the final product resonates with consumers.

Moreover, considering the specifics of digital printing on fabric is essential. This includes understanding the textile’s texture, color absorption, and material composition, which can all influence the final outcome. The interplay of design and material knowledge ultimately defines the quality of the DTF transfer, showcasing the importance of skilled design in achieving a successful print.

Recent Advancements in DTF Technology

With rapid technological advancements in DTF printing, manufacturers are introducing new systems that enhance production efficiency and quality. The evolution of DTF printers allows for higher resolution outputs while maintaining faster printing speeds. This innovation is crucial as businesses must adapt to ever-growing market demands for quick turnaround times without compromising on quality.

Additionally, newer DTF technologies are focusing on integrating sustainability within their production processes. Many companies are transitioning to eco-friendly inks and recyclable materials, aligning with global efforts toward sustainable printing methods. These advancements reflect a commitment not just to quality and efficiency, but also to responsible production practices that appeal to environmentally conscious consumers.

Sustainability in DTF Printing

Sustainability is becoming a key driver in the textile printing industry, and DTF printing is no exception. This innovative method utilizes water-based inks and recyclable PET films, minimizing environmental impact compared to traditional printing processes. The industry’s transition to more sustainable printing methods is in direct response to consumer demand for eco-friendly products, enabling brands to align their operations with sustainable practices.

Moreover, the DTF printing process highlights the importance of waste reduction by optimizing production techniques that limit leftover materials. By promoting an environmentally responsible approach, businesses can enhance their market appeal while contributing to global sustainability goals. Thus, embracing DTF technology not only benefits production efficiency but also supports broader ecological initiatives.

Applications and Versatility of DTF Printing

The versatility of DTF printing allows it to serve a diverse array of applications across different textile products. From vibrant cotton t-shirts to polyester blends, this technology caters to various customer needs, enhancing creativity in the apparel industry. This adaptability stands in contrast to more traditional methods like screen printing, emphasizing DTF’s growing prominence in the market.

The ability to print on a wide range of fabrics also emphasizes digital printing on fabric’s advantages, enabling designs that were once challenging to achieve. As industries continue to explore innovative printing solutions, DTF technology is emerging as a powerful contender, paving the way for new possibilities and creative expression in fabric applications.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process, or Direct-to-Film printing, involves several key stages including design creation, printing on transfer film, applying powdered adhesive, curing, and heat pressing. This efficient method allows for high-resolution images to be transferred onto various fabrics, resulting in vibrant and durable prints.

What materials are used in DTF transfers?

DTF Transfers utilize special PET (Polyethylene Terephthalate) films and eco-friendly, water-based inks. The use of these materials ensures that the prints are not only vivid but also sustainable, aligning with modern printing methods that prioritize environmental responsibility.

Can DTF printing be used on different types of fabrics?

Yes, DTF printing is highly versatile and can be used on a wide range of fabrics, including cotton, polyester blends, and more. This flexibility makes DTF transfers an attractive choice for various textile products, enhancing their appeal in the market.

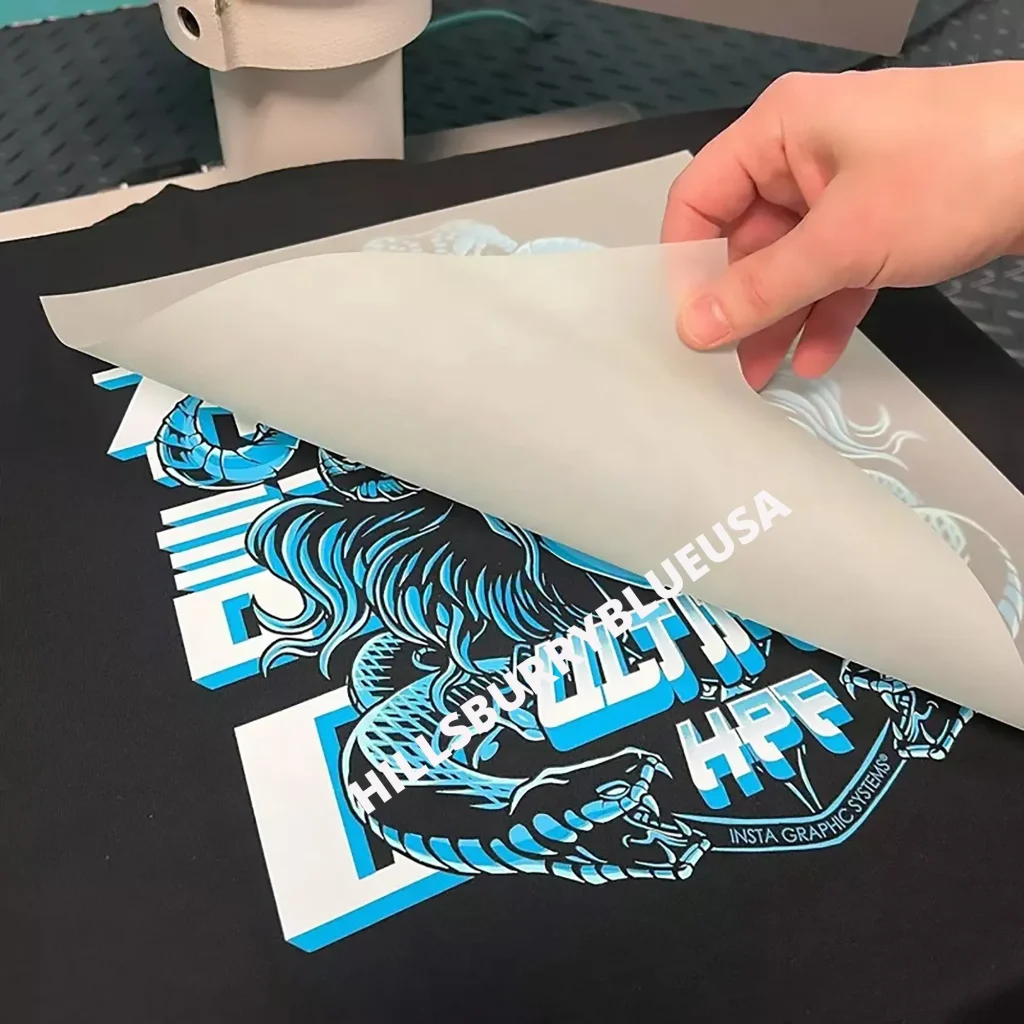

How does the heat pressing stage work in the DTF transfer process?

During the heat pressing stage of DTF transfers, the printed film is placed on the fabric and subjected to high temperature. This activates the powdered adhesive, causing it to bond the ink firmly to the fabric, resulting in a soft, durable finish that integrates seamlessly with the material.

What are the benefits of using DTF transfers compared to other printing methods?

DTF transfers offer superior quality and durability compared to traditional methods like screen printing. They provide high-resolution prints, are versatile across different fabrics, and feature eco-friendly processes, making them a sustainable option for modern businesses.

What recent advancements are shaping the future of DTF printing?

Recent advancements in DTF printing technologies include faster printing speeds, higher resolutions, and a shift towards sustainable materials. These developments not only enhance production efficiency but also meet the growing consumer demand for eco-friendly printing solutions.

| Stage | Description |

|---|---|

| 1. Design Creation | Artists use graphic design software to create high-resolution images. Factors such as color accuracy and positioning are crucial for quality. |

| 2. Printing on Transfer Film | The design is printed onto PET film with eco-friendly water-based inks, ensuring vibrant output. |

| 3. Powder Adhesion | A heat-activated powder adhesive is sprinkled on the wet ink to ensure a strong bond to the fabric. |

| 4. Curing the Adhesive | The films are cured using heat to solidify the glue, ensuring a strong bond during heat pressing. |

| 5. Heat Pressing | The film is heat pressed onto the fabric making the graphic integral to the fabric, resulting in a breathable finish. |

Summary

DTF Transfers represent a transformative approach in the textile printing industry, combining high-quality output with eco-friendly practices. Understanding the intricacies of the DTF transfer process—notably the steps from design creation to heat pressing—reveals how these techniques offer exceptional versatility for various applications. As the industry embraces advancements in technology and sustainability, DTF transfers will continue to lead innovation, making them an appealing choice for businesses and artists aiming to enhance their fabric printing capabilities.