DTF transfers, or Direct to Film transfers, represent a groundbreaking advancement in the field of custom printing. As digital printing innovations continue to reshape the industry, DTF printing technology stands out due to its ability to produce high-quality, vibrant designs that can be seamlessly applied to various fabrics. This revolutionary method is not only effective for apparel printing solutions but also emphasizes sustainable printing practices that reduce waste compared to traditional methods. With an increasing demand for customized products, the market for DTF transfers is expanding rapidly, providing businesses with the opportunity to meet consumer preferences for both personalization and eco-friendliness. As we delve into the future of custom printing, it is clear that DTF transfers are here to stay, leading the way in both quality and sustainability.

In the realm of personalized textile production, Direct to Film (DTF) technology is revolutionizing the way designs are applied to garments and accessories. Often referred to as the latest frontier in apparel decoration, DTF printing has quickly emerged as a leading choice among designers and manufacturers seeking efficient and environmentally responsible printing solutions. The methodology behind these transfers not only ensures stunning visual outcomes but also prioritizes sustainable practices that resonate with today’s conscious consumers. As the demand for unique and high-quality printed material grows, this innovative printing technique is paving the way for a future where custom pieces are both fashionable and eco-conscious. The transition toward adopting DTF transfers symbolizes a significant leap in the evolution of custom printing, aligning with the broader trends of digital transformation and responsible production.

Understanding DTF Transfers: A Game-Changer in Apparel Printing

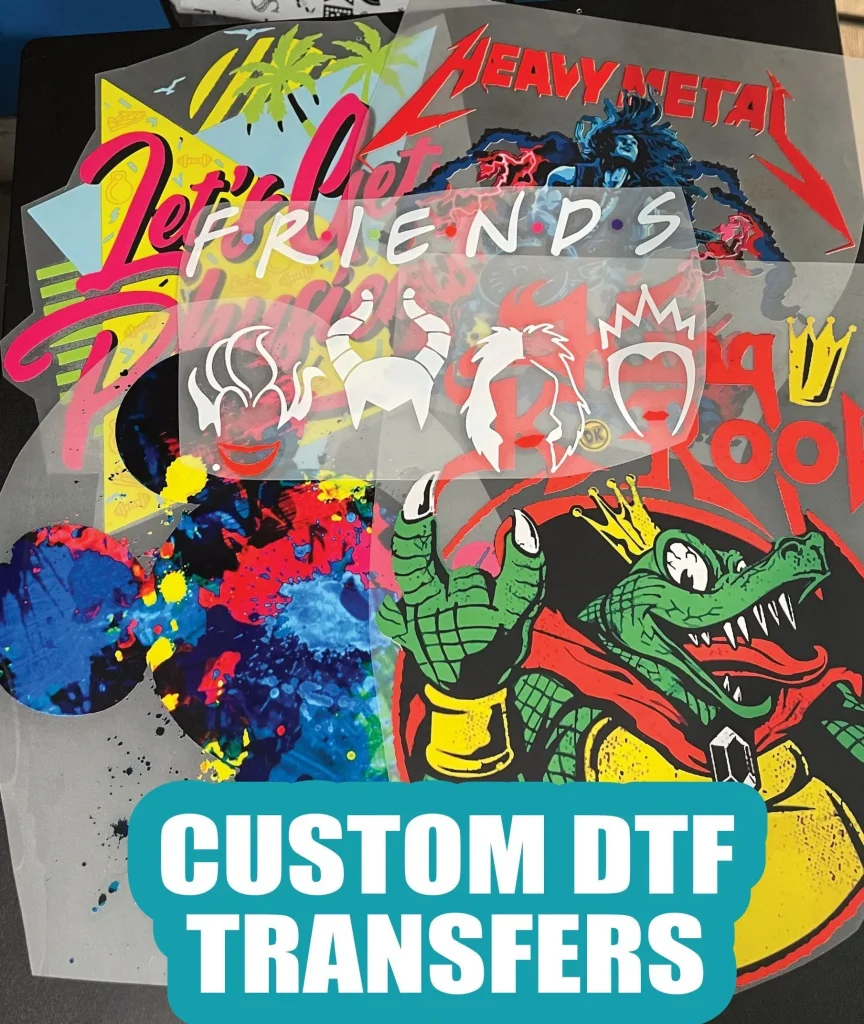

DTF transfers, or Direct to Film transfers, are revolutionizing the custom printing industry, particularly in apparel applications. This innovative technology allows designers to create high-quality prints by applying vibrant designs directly to specially coated films. These films can then be seamlessly transferred to fabrics using heat and pressure, ensuring durability and vivid colors that stand the test of time. In addition to their visual appeal, DTF transfers offer versatility across numerous fabric types, allowing for extensive customization options that cater to diverse consumer preferences.

Moreover, the rise of DTF transfers is indicative of a broader trend in digital printing innovations. As consumers increasingly seek personalized products, more businesses are adopting DTF technology to meet their printing needs efficiently. This method not only enhances the quality of prints but also speeds up the production process. Thus, DTF transfers are not simply a fleeting trend; they represent a significant leap forward in how apparel can be printed, combined with sustainability measures that resonate with today’s environmentally-conscious buyer.

Sustainable Practices in Custom Printing

Sustainability is at the forefront of modern printing, and when it comes to DTF transfers, this technology stands out as a leader in eco-friendly practices. Traditional printing methods often consume substantial resources and produce significant waste, contributing to environmental decline. In contrast, DTF transfers minimize waste significantly by using less ink and eliminating the need for harmful solvents and chemicals prevalent in other printing techniques. This shift toward sustainable printing methods is not just a trend; it’s a necessity in building a more responsible future for manufacturing.

Furthermore, as businesses strive to make greener choices in their production processes, DTF transfers easily integrate into sustainable apparel printing solutions. Companies can reduce their carbon footprint while still delivering high-quality custom products that appeal to conscientious consumers. The growing demand for sustainable options in the market indicates an enduring shift in consumer behavior, making DTF printing a reliable choice for businesses aiming to be part of this sustainable movement.

The Benefits of DTF Printing Technology

DTF printing technology brings a host of advantages that traditional printing methods cannot match. One of the key benefits is the exceptional quality of the prints, as DTF transfers yield vibrant, full-color designs with intricate details. This high-resolution capability allows for creativity to flourish, enabling designers and brands to bring their visions to life with precision and clarity. Additionally, because the transfer process is straightforward and requires minimal equipment, it simplifies operations for small businesses and startups looking to enter the custom apparel market.

Another significant advantage is the flexibility this technology offers. DTF transfers can be applied to a variety of substrates, including cotton, polyester, and blends, making them ideal for diverse apparel lines. Brands can easily adapt their products to cater to different customer demographics, meeting various fashion tastes and preferences. In an increasingly competitive market, the adaptability of DTF printing technology positions it as a vital tool for businesses aiming to thrive and innovate.

Adopting Digital Printing Innovations for Competitive Advantage

The integration of digital printing innovations, such as DTF transfers, is becoming essential for businesses aiming to maintain a competitive edge in the apparel industry. In today’s fast-paced market, the ability to deliver customized products quickly is crucial, and DTF printing allows for agile production workflows. The rapid turnaround times afforded by this technology enable brands to respond swiftly to consumer trends and demands, ensuring they stay ahead of the curve.

Additionally, DTF printing supports a more personalized customer experience, as consumers increasingly seek unique products that reflect their individual styles. Businesses that leverage these digital printing innovations not only enhance their product offerings but also build strong connections with their audience by providing tailored solutions that resonate with their values and desires.

Why Businesses Should Invest in DTF Transfers

Investing in DTF transfers can yield significant long-term benefits for any custom printing business. With its capacity for high-quality output and the reduction of operational costs through efficient printing, DTF technology is a smart investment. As companies search for reliable printing solutions to support their growth, DTF transfers emerge as a front-runner not only because of their output quality but also due to their environmentally friendly nature.

Moreover, the initial investment in DTF printing equipment can pay off quickly as businesses streamline their processes and enhance their product offerings. Companies that prioritize this technology will likely see increased customer satisfaction and loyalty, as consumers are drawn to brands that not only provide quality products but also demonstrate a commitment to sustainable practices. Investing in DTF transfers thus aligns financial goals with broader environmental responsibilities, positioning businesses favorably for future success.

The Future of Custom Printing with DTF Technology

Looking forward, it is clear that DTF technology will play a pivotal role in the future of custom printing. As environmental concerns continue to dominate consumer choices, DTF transfers provide a solution that aligns with the demand for sustainability without compromising quality. The continuous advancements in DTF printing technology promise even greater efficiencies and capabilities, further solidifying its place within the industry.

Furthermore, as digital printing innovations evolve, they will undoubtedly enhance DTF capabilities, opening doors to even more creative applications. This evolution will play a crucial role in how designers and brands engage with their customers, fostering not just a transactional relationship but a deeper emotional connection through the art of personalization. As we embrace the future, DTF transfers will undoubtedly stand at the forefront of this exciting new era in custom printing.

Frequently Asked Questions

What are the benefits of using DTF transfers for custom printing?

DTF transfers, or Direct to Film transfers, offer numerous benefits for custom printing, including vibrant and durable prints, versatility across various fabrics, and a more sustainable process with less waste than traditional methods. This makes DTF printing technology ideal for businesses seeking to enhance their apparel printing solutions.

How does DTF printing technology compare to traditional screen printing?

DTF printing technology is considered superior to traditional screen printing in several ways, particularly in terms of efficiency and sustainability. DTF transfers produce high-quality prints with lower production waste, making them a better choice for eco-conscious brands looking to adopt sustainable printing practices.

Why is sustainability important in the context of DTF transfers?

Sustainability is crucial in DTF transfers because this method significantly reduces waste and the use of harmful solvents compared to traditional printing. As consumers increasingly prioritize eco-friendly products, DTF technology aligns with this demand, offering businesses a way to meet sustainability goals while providing top-notch custom printing.

Can DTF transfers be used on different types of materials?

Yes, DTF transfers can be applied to a wide variety of materials, making them versatile for custom apparel printing. Whether it’s cotton, polyester, or mixed fabrics, DTF printing technology delivers exceptional results, providing the flexibility needed for any printing project.

What role do digital printing innovations play in enhancing DTF transfers?

Digital printing innovations are essential to enhancing DTF transfers as they improve print quality, reduce production time, and increase customization options. With advancements in DTF printing technology, businesses can achieve more intricate designs and quicker turnaround times, strengthening their offerings in custom printing.

How does DTF printing technology contribute to eco-friendly apparel printing solutions?

DTF printing technology contributes to eco-friendly apparel printing solutions by minimizing waste and utilizing non-toxic inks that are less harmful to the environment. This approach not only helps businesses reduce their carbon footprint but also appeals to environmentally conscious consumers who value sustainable practices.

| Key Points | Details |

|---|---|

| DTF Transfers Defined | DTF transfers print designs onto a special film to transfer onto fabrics using heat and pressure. |

| Sustainability Benefits | DTF transfers reduce printing waste by up to 50% compared to traditional screen printing. |

| Customizability | This method allows for vibrant, durable prints that cater to diverse materials, particularly in apparel. |

| Market Demand Alignment | DTF technology meets the rising consumer demand for eco-friendly and customizable products. |

Summary

DTF transfers are revolutionizing the custom printing industry and are here to stay. With their unique capability to minimize waste and enhance the vibrancy of prints, DTF transfers meet the growing demand for eco-friendly solutions in a market that prizes customization. By offering sustainable and efficient printing options, DTF transfers not only appeal to businesses but also align with the values of conscious consumers, making them a pivotal innovation in the world of custom printing.