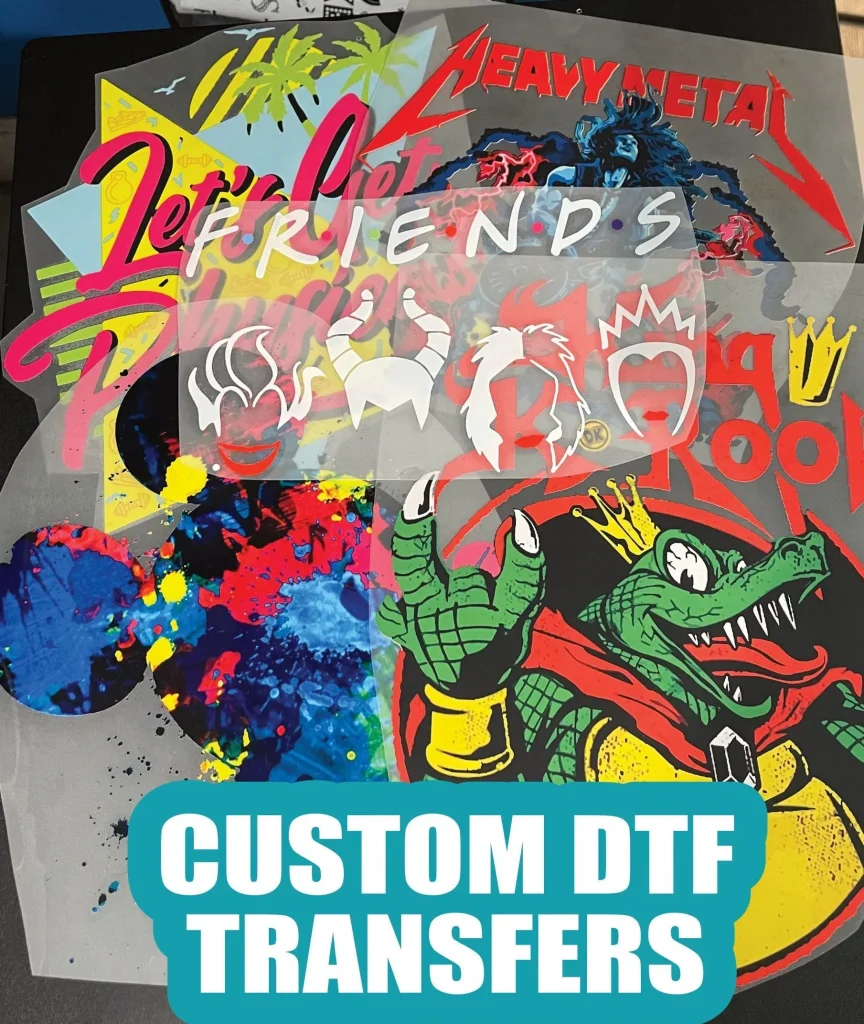

DTF transfers, or Direct to Film transfers, have emerged as a game-changer in the textile printing industry, allowing for high-quality, vibrant prints on various fabrics. This innovative technique stands out for its versatility and ability to produce intricate designs with a broad color range, setting it apart from traditional printing methods. As businesses and DIY enthusiasts continue to explore DTF transfers, understanding the essential techniques and equipment is crucial for optimal results. In this article, we dive into the fascinating world of DTF printing techniques, offering heat press tips and insights into achieving stunning custom fabric printing. Whether you’re a seasoned professional or just starting out, mastering DTF transfers will elevate your textile printing game and open up new creative possibilities.

In the realm of textile printing, Direct to Film (DTF) techniques have redefined how designs are applied to fabrics. Often referred to as film transfer printing, this method uses specialized films to transfer detailed images through a heat press, making it an excellent choice for custom fabric applications. With its capacity for high-resolution outputs and color vibrancy, DTF printing provides an alternative to traditional screen printing. As we explore this fascinating technique, we will highlight essential heat press tips and other printing strategies that contribute to successful outcomes, empowering creators and entrepreneurs in the growing field of textile decoration.

Understanding DTF Printing Techniques

DTF (Direct to Film) printing has emerged as a game-changing technique in the textile printing industry. It works by printing designs onto a special film and subsequently transferring them onto the fabric using a heat press. This method stands out for its ability to produce vivid, intricate designs without the color limitations often found in traditional screen printing. By using water-based inks, DTF transfers also position themselves as an eco-friendly option, appealing to both businesses and conscious consumers.

What makes DTF printing so attractive is the flexibility it offers. From corporate branding to personalized apparel, the technique allows for an expansive range of color combinations and gradients. Additionally, it empowers users to experiment with different materials, ensuring that they can create custom fabric prints that are not only aesthetically pleasing but also durable. Understanding these techniques can greatly enhance the overall impact of your printed designs.

Essential Equipment for DTF Transfers

To embark on your DTF printing journey, having the right equipment is paramount. The foundation of DTF printing begins with a high-quality DTF printer that can deliver high-resolution images. Investing in superior transfer films and inks will also influence the outcome. Ensure that the transfer films are compatible with your inks, as this affects color vibrancy and print quality significantly. Without proper equipment, the richness of the DTF printing process can be diminished.

Using a reliable heat press machine is equally critical in DTF transfers. Consistent heat and pressure during application ensure that the ink bonds effectively with the fabric, leading to enduring prints. As a best practice, familiarize yourself with pre-treatment solutions that enhance ink adherence on the transfer film. By equipping yourself with the recommended tools and supplies, you’re positioning yourself on the path to success in this innovative printing technique.

Heat Press Tips for Effective DTF Printing

The heat press process is a pivotal step in ensuring the success of your DTF transfers. Applying the right amount of heat and pressure can dramatically affect the quality and longevity of your prints. Typically, a temperature range of 160-180°C (320-356°F) is recommended for most fabrics. Adjusting the pressing time between 15 to 25 seconds will make all the difference depending on the material you are working with. The precision in timing and temperature is key to achieving optimal adhesion.

It’s also vital to experiment with the pressure settings of your heat press. Different fabrics react uniquely under heat; certain materials may require additional pressure for adequate bonding. Once the pressing is complete, allow the transfer to cool down briefly before peeling the carrier film. This cooling phase can enhance the adhesion, ensuring that your designs do not fade or peel over time, ultimately yielding durable custom fabric prints.

Care Practices for DTF Printed Items

After you have created stunning DTF printed items, conveying proper care instructions to your clients is essential. Washing these garments inside out can prevent unnecessary wear on the printed designs. Furthermore, using mild detergents that are free from harsh chemicals will help maintain the integrity of the print. It’s important to instill these habits in customers to ensure the prints last longer.

Another critical tip is advising clients against ironing directly over the printed area. Instead, suggest the use of a protective cloth or to iron the garment inside out. Direct heat can compromise the print quality and lead to potential damages. By following these simple care practices, clients can enjoy their DTF printed items for years to come without the risk of fading or deterioration.

Addressing Common Challenges in DTF Transfers

Like all printing methods, DTF transfers can present challenges. The most common issues include blurring, fading, and adhesion problems. To combat blurring or fading, ensure that your printer settings are correctly configured, and always use high-resolution images. Color inconsistency can also arise—investing time in understanding color profiles is essential for achieving the best results that align with your design vision.

Additionally, adhesion issues can often stem from inadequate pre-treatment or incorrect temperature and pressure settings during the heat press process. Staying vigilant with these aspects can help prevent many common problems that printers face. Establishing a consistent workflow with checks at each stage will greatly enhance the quality of your DTF transfers and the overall satisfaction of your customers.

Creative Applications of DTF Transfers in Textile Printing

DTF transfers open up a realm of creative possibilities in the textile printing world. From producing custom t-shirts to unique promotional items, the versatility of DTF printing accommodates various design complexities, making it a preferred choice among both amateur and professional printers. Artists and designers can leverage this technique to create stunning fabric prints that are eye-catching and expressive, perfect for encapsulating personal style or brand identity.

Moreover, the ability to work on diverse fabrics—from cotton to polyester—empowers users to explore more creative applications. DTF transfers are not limited to apparel; they can be utilized in creating bespoke home textiles, such as cushions and curtains, which adds a personalized touch to living spaces. This flexibility not only expands the market opportunities for DTF printing but also invites innovation in designs and applications across multiple sectors.

Frequently Asked Questions

What are DTF transfers and how do they work in textile printing?

DTF transfers, or Direct to Film transfers, are a cutting-edge textile printing method where designs are printed onto a special film, then transferred to fabric using heat and pressure. This technique allows for vibrant colors and intricate designs, making it a popular choice for custom fabric printing.

What equipment do I need to start using DTF printing techniques?

To start DTF printing, you’ll need specific equipment including a DTF printer that can handle high-resolution prints, high-quality DTF transfer films, water-based DTF inks, a reliable heat press, and pre-treatment solutions to enhance ink adherence on fabrics.

What are some heat press tips for achieving the best results with DTF transfers?

For optimal results with DTF transfers, set your heat press temperature between 160-180°C (320-356°F), press for 15-25 seconds, and adjust pressure settings based on the fabric type. Allow the transfer to cool slightly before peeling for better adhesion.

Can I use DTF transfers on all types of fabrics?

DTF transfers can be used on a variety of fabrics, including cotton, polyester, and blends. However, it is important to test each fabric type for compatibility, as some may respond better to the DTF printing process than others.

What are the common challenges faced with DTF printing and how can I overcome them?

Common challenges in DTF printing include blurring and fading of prints, poor adhesion, and color inconsistencies. To overcome these issues, ensure proper printer settings, conduct adequate pre-treatment, and use high-resolution images with an appropriate color profile.

How should I care for items printed with DTF transfers to maintain their quality?

To maintain the quality of DTF printed items, wash them inside out with mild detergents, avoid harsh chemicals, and refrain from ironing directly on the print. Use a protective cloth or iron inside out for safe results.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | A technique of printing designs onto a special film and transferring it to fabrics using heat and pressure, allowing for vibrant, eco-friendly prints. |

| Equipment Needed | DTF Printer, Transfer Film, DTF Inks, Heat Press, Pre-treatment Solutions |

| Techniques for Success | Pre-treat films, adjust printer settings, heat press with proper time and temperature. |

| Post-Processing Care | Advise washing inside out and avoiding direct ironing on prints for longevity. |

| Common Challenges | Blurring, adhesion problems, color inconsistencies and solutions to address each. |

Summary

DTF transfers represent a breakthrough in textile printing technology. This innovative method allows for high-quality, vibrant designs that can be applied to various fabrics, making it a versatile option for businesses and creators alike. By understanding the fundamental techniques, from proper equipment selection to heat pressing methods, users can greatly enhance their DTF printing experience. Embracing these practices not only ensures optimal print quality but also addresses common challenges, paving the way for successful and durable printed products. As the market for personalized and custom items grows, mastering DTF transfers will enable creators to stand out in a competitive landscape.