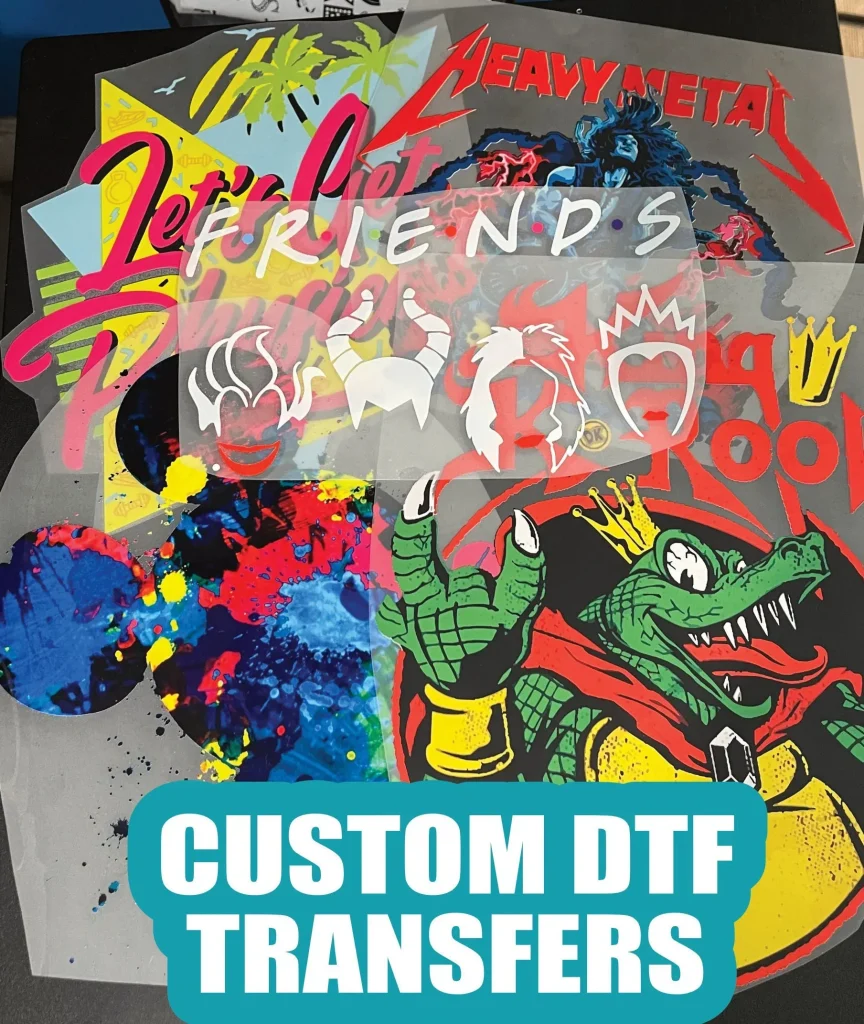

DTF transfers, or Direct to Film transfers, have revolutionized the fabric printing industry in recent years, providing an innovative and efficient solution for vibrant designs on various materials. Whether you’re a budding entrepreneur aiming to offer captivating custom apparel or a creative individual eager to enhance your DIY projects, mastering DTF transfers is key to unlocking high-quality results. This guide delves into the intricate DTF transfer process, revealing the remarkable benefits of DTF printing, essential equipment needed, and expert tips to excel in this craft. With DTF printing technology at your fingertips, you can achieve stunning visuals with durability and flexibility that rival traditional methods. Explore the exciting world of DTF transfers and discover the creative potential that awaits you!

Direct to Film (DTF) printing techniques are fast becoming a staple in the realm of textile decoration, merging artistry with functionality seamlessly. This method, often referred to as film transfer printing, allows for intricate designs to be applied to a variety of fabrics, making it a popular choice among apparel decorators and hobbyists alike. By utilizing specialized materials and equipment, understanding how to effectively execute the DTF transfer process can unlock a plethora of opportunities for custom garment creation. The advantages of this printing style—such as its adaptability to different textiles and vibrant print quality—make it an incredible tool for both personal and professional projects. Embarking on a journey into the realm of film printing will provide insights into the benefits and techniques that can elevate your fabric designing skills.

Understanding DTF Printing Technology

DTF printing technology has transformed the way designs are transferred onto fabrics, offering an innovative approach that bridges the gap between traditional screen printing and digital printing. Unlike other methods, DTF relies on a unique combination of specialized inks and adhesive powders that guarantees vibrant and lasting prints. This approach not only enhances the design potential but also allows for an easier and more efficient process. As this technology evolves, the printing industry witnesses a rise in interest, with businesses eager to adopt this cost-effective and high-quality solution.

A major component of DTF printing is the equipment used in the process. DTF printers, which utilize specific Direct to Film inks, ensure that colors pop and detail remains sharp, even with intricate patterns. Additionally, the hot-melt adhesive powder plays a crucial role in ensuring that designs adhere properly to various fabrics. By grasping the fundamentals of DTF printing technology, businesses can make informed choices about their equipment and ensure that they deliver top-notch products.

Frequently Asked Questions

What is DTF printing and how does it differ from other printing methods?

DTF printing, or Direct to Film printing, is a method of applying designs to fabric via a special film. Unlike screen printing, which uses stencils for each color, DTF transfers allow for vibrant multi-colored designs to be printed in one process on a PET film. This method is faster, more versatile, and capable of producing high-quality prints on various materials.

What equipment do I need for the DTF transfer process?

To begin DTF transfers, essential equipment includes a DTF printer, which uses specialized inks for printing on PET film, a heat press machine for transferring designs onto fabric, and hot-melt adhesive powders to ensure proper adhesion of the print to the material.

How do I perform a DTF transfer?

The DTF transfer process involves several steps: first, use graphic design software to create your artwork; then, print the design onto a PET film with a DTF printer. Apply adhesive powder while the ink is wet, heat cure the film to bond the adhesive, and finally, use a heat press to transfer the design onto your chosen fabric.

What are the benefits of DTF transfers compared to traditional printing methods?

DTF transfers offer numerous benefits, including versatility across various fabric types, high-quality prints with vibrant colors, cost-effectiveness for small batches, and durability that resists cracking and fading, making them an ideal choice for custom garment printing.

Can I use DTF transfers on all types of fabrics?

Yes, DTF transfers are versatile and can be used on a wide range of fabrics, including cotton, polyester, and their blends. This adaptability makes DTF printing suitable for various applications, including apparel and accessories.

What should I consider for successful DTF printing?

For successful DTF printing, choose high-quality films and adhesive powders designed for DTF, experiment with your printer settings for optimal output, ensure your heat press temperature and pressure are correctly set based on your fabric, and focus on strong design skills to enhance print success.

| Key Aspect | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs on special film for transfer onto fabric, using specialized inks. |

| How DTF Transfers Work | Steps include design creation, printing on film, applying adhesive powder, heat curing, heat press transfer, and peeling. |

| Advantages of DTF Printing | Versatile for various materials, delivers high-quality prints, cost-effective for small batches, durable prints. |

| Equipment Needed | Requires a DTF printer, heat press machine, and DTF adhesive powders. |

| Trends in DTF Technology | Advancements in inks and materials increasing versatility. |

| Best Practices | Choose high-quality materials, perfect printing settings, master heat press techniques, and enhance design skills. |

Summary

DTF Transfers are transforming the fabric printing industry with their innovative approach to garment decoration. This comprehensive guide highlights the essentials of DTF transfers, showcasing the method’s versatility, high-quality output, and the necessary equipment to get started. By understanding the detailed process of DTF printing—from design creation to heat press application—users can confidently embark on their custom printing journey. As technology advances, staying informed about trends and best practices will empower businesses and DIY enthusiasts alike to thrive in the vibrant world of DTF Transfers. Embrace this printing revolution to unlock creative potential and meet evolving market demands.