In the vibrant world of custom apparel, DTF transfers—short for Direct to Film transfers—are revolutionizing the way designs are applied to fabrics. This innovative technique simplifies the process of transferring intricate graphics onto various clothing materials, making it a standout option among screen printing alternatives. DTF printing benefits include exceptional color vibrancy and long-lasting durability, appealing to both professional designers and hobbyists alike. As more people explore custom apparel design, understanding DTF transfers becomes essential for enhancing creativity and productivity. This introductory guide aims to illuminate the journey from initial concept to final creation, showcasing the power and versatility of DTF transfers in the realm of apparel printing.

Also known as Direct to Film printing, this method has gained traction in the custom clothing industry due to its efficiency and high-quality results. Unlike traditional heat transfer printing or screen printing methods, DTF printing utilizes a specialized film that allows for intricate detail and rich color profiles. This technique offers numerous advantages, particularly for those looking to create personalized apparel, as it can accommodate a wide range of fabric types. As the demand for unique, custom-designed clothing increases, mastering the principles of DTF transfers can significantly enhance any designer’s toolkit. Explore the applications and possibilities that this advanced printing technology provides for today’s creative entrepreneurs and apparel enthusiasts.

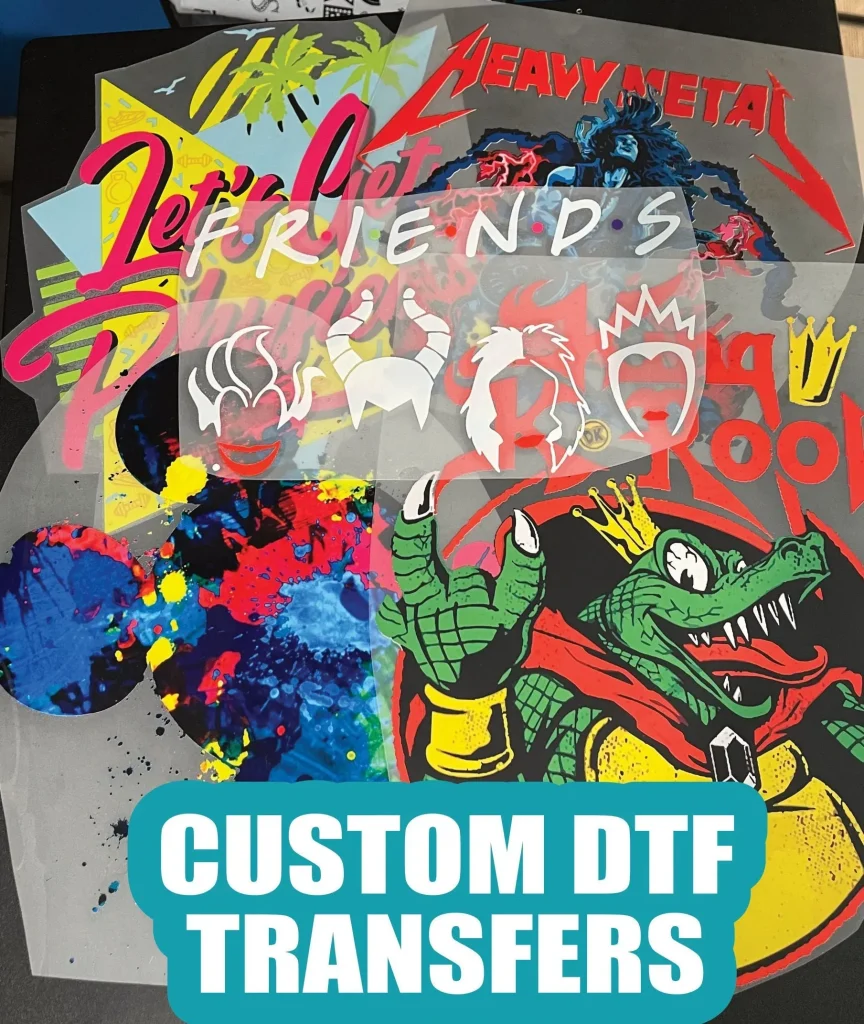

Exploring the Advantages of DTF Transfers

DTF transfers, or Direct to Film transfers, present numerous advantages for custom apparel designers. One of the most significant benefits is the versatility they offer in fabric compatibility. Unlike traditional screen printing, which may be limited to certain types of fabrics, DTF transfers can effectively be applied to a wide range of materials including cotton, polyester, and blends. This opens up a world of possibilities for designers looking to create unique garments that resonate with diverse consumer preferences.

Furthermore, DTF transfers are renowned for their durability. Once cured properly, the designs maintain their vibrancy and flexibility even after multiple washes, making them ideal for everyday wear. This high durability not only enhances customer satisfaction but also reduces the need for reprints, saving time and resources for designers. Ultimately, DTF transfers allow for greater creativity without sacrificing quality, establishing themselves as a powerful tool in the realm of custom apparel.

Custom Apparel Design with DTF Technology

Custom apparel design has evolved significantly with the introduction of DTF technology. This printing method enables designers to bring their creative visions to life while offering a wide array of design possibilities. With DTF transfers, artists can print intricate graphics, vibrant colors, and personalized designs with ease. The ability to work with high-resolution images ensures that every detail is captured, making it perfect for custom logos and artistic expressions on clothing.

Additionally, DTF printing allows for relatively quick turnarounds on custom order requests. Designers can create small batches or even single pieces without facing the higher setup costs associated with traditional methods like screen printing. This agility makes DTF an attractive option for businesses catering to niche markets or those who prioritize personalized customer interactions.

The Process of Creating Stunning DTG Transfers

Creating stunning DTG transfers begins with the conceptualization phase, where designers brainstorm and develop their unique ideas. Utilizing powerful graphic design software like Adobe Illustrator or CorelDRAW is essential for drafting high-quality digital artwork. It’s important to keep resolution in mind, as designs need to be at least 300 DPI to ensure clarity and vibrancy once transferred onto apparel.

Once the design is ready, the next steps involve adjusting color profiles and ensuring that the layout fits the intended garment. Accurate color management, including the use of CMYK over RGB, can significantly impact the final outcome. By considering these technical aspects, designers can avoid common pitfalls and ensure that their DTF transfers look exceptional once printed.

Technical Considerations for DTF Printing Success

Technical expertise plays a crucial role in the success of DTF printing. When preparing designs, integrating accurate color management techniques is vital for achieving the best results. Designers must familiarize themselves with how colors on-screen translate to printed fabric to avoid discrepancies that could affect the final product. This involves selecting the right color profiles and experimenting with different shades to perfect the design.

Layout and size are equally important considerations. Designers should ensure that their artwork fits the specified dimensions while accommodating any folds or seams on garments. By meticulously planning these details, designers can create images that not only stand out but also naturally align with the fabric’s structure, ensuring a seamless transfer.

DTF Printing Trends to Watch

The landscape of DTF printing is continuously evolving with emerging trends that are reshaping the market. One of the most notable trends is the increasing emphasis on sustainability. As consumers become more environmentally conscious, there is a growing demand for DTF printing processes that utilize eco-friendly inks and biodegradable materials. Designers who adopt sustainable practices can not only appeal to this market but also contribute positively to the environment.

Another trend to watch is the rise of personalization within the DTF printing sector. Customers now desire unique, customized clothing options that reflect their individual styles. Designers who integrate personalization into their offerings can distinguish themselves from competitors while meeting consumer expectations for bespoke apparel.

Navigating the Business Side of DTF Printing

Navigating the business side of DTF printing requires understanding market demands and consumer preferences. As the industry shifts towards personalized and customized offerings, designers must adapt to these changes by creating products that reflect current trends. This includes leveraging social media and digital marketing strategies to showcase unique designs and engage a broader audience.

Additionally, managing production efficiency is critical for profitability. DTF printing allows for cost-effective short runs, which can be advantageous for small businesses looking to minimize waste and optimize their inventory. By analyzing production metrics and understanding customer needs, designers can effectively scale their operations while maintaining high-quality outputs.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film transfers, utilize a digital printing method that involves printing your design onto a special film using specialized inks. The printed film is then coated with an adhesive powder and cured before being transferred onto fabrics with a heat press. This process allows for vibrant colors and detailed designs on various textiles.

What are the key benefits of using DTF printing for custom apparel design?

The benefits of DTF printing in custom apparel design include its versatility across different fabric types, high durability of designs after washing, and cost-effectiveness for small runs. This makes DTF transfers an appealing choice for producing customized clothing.

How does DTF printing compare to traditional screen printing alternatives?

Compared to traditional screen printing alternatives, DTF printing offers quicker production times, greater design flexibility, and the ability to print detailed images on diverse fabrics. It is particularly advantageous for custom apparel design with complex graphics.

What technical considerations should I keep in mind when designing for DTF transfers?

When designing for DTF transfers, ensure your artwork is high resolution (300 DPI), use accurate CMYK color profiles, and plan your layout to account for garment folds or seams. These factors will enhance the quality and accuracy of your final prints.

Can DTF Transfers be applied to all fabric types?

Yes, one of the key benefits of DTF transfers is their versatility; they can be applied to a wide range of fabrics including cotton, polyester, and blends. This makes them suitable for various custom apparel applications, from t-shirts to hoodies.

What are the current trends in DTF printing I should be aware of?

Current trends in DTF printing include a growing focus on sustainability with eco-friendly inks and materials, advancements in printing technology for speed and efficiency, and a rising demand for personalized and customizable clothing options. Staying updated with these trends can help your custom apparel designs remain competitive.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | Digital printing method using specialized inks on film to transfer designs to fabrics. |

| Benefits of DTF Printing | 1. Versatility in Fabrics 2. High Durability 3. Cost-Effectiveness |

| Designing for DTF Transfers | Step 1: Conceptualize your design using graphic software. Step 2: Consider color management and layout. Step 3: Prepare for printing by following specific steps for DTF. |

| Current Trends | 1. Sustainability Practices. 2. Technological Advancements. 3. Personalization and Customization. |

Summary

DTF Transfers are revolutionizing the custom apparel industry by providing an innovative, efficient solution for transferring designs onto fabrics. This technology enables designers to create vibrant, high-quality prints that are durable and adaptable to various materials. As the demand for personalized clothing rises, DTF transfers offer unique advantages, including cost-effectiveness and ease of use. By mastering the intricacies of designing with DTF transfers, creators can expand their product offerings and cater to a growing market of customization enthusiasts.